Ever wondered why engineers and manufacturers reach for aluminum screws in so many modern projects? Aluminum screws are threaded fasteners made from high-grade aluminum alloys like 6061-T6 or 7075. They’re designed to join components where weight savings, corrosion resistance, and electrical conductivity are essential. You’ll notice these fasteners in aerospace, automotive, electronics, and marine industries, where every gram matters and harsh conditions are the norm. Compared to traditional steel or stainless steel screws, aluminum fasteners offer a unique blend of properties that make them invaluable for specific applications.

So, when should you choose aluminum screws over alternatives? Imagine you’re assembling a lightweight drone, a laptop chassis, or a coastal structure. In these scenarios, the benefits of aluminum—being up to 60% lighter than stainless steel and naturally corrosion-resistant—shine through. Their nonmagnetic nature makes them ideal for sensitive electronics, while their thermal and electrical conductivity supports specialized engineering needs. However, keep in mind that aluminum screws are best suited for non-structural or lightly loaded joints, as their tensile strength is lower than that of most steel fasteners.

Sounds complex? Let’s break down the key differences at a glance:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance |

|---|---|---|---|

| Aluminum | 2.7 | 310–550 | Excellent (forms protective oxide layer) |

| Stainless Steel | 7.8 | 500–800 | Very Good (but galvanic risk with aluminum) |

| Carbon Steel | 7.8 | 400–600 | Moderate (requires coating for corrosion protection) |

As you can see, aluminum fasteners are roughly one-third the density of steel, making them a top pick for weight-sensitive assemblies. They naturally resist corrosion by forming an oxide layer, which is a big plus in marine or humid environments. However, their tensile strength is lower—so for high-load structural joints, a steel or stainless alu bolt may be more appropriate. Aluminum is also nonmagnetic and easier to machine, which is why it’s so common in electronics and custom assemblies.

Choosing the right head and drive style can make your assembly process faster and more reliable. Here’s a quick guide:

Aluminum machine screws are typically used in pre-tapped holes or with matching nuts, providing precision and reusability. In contrast, self-tapping aluminum screws cut their own threads as they’re driven into softer materials, like thin sheet aluminum or plastic. This distinction is crucial: machine screws need a prepared thread, while self-tapping types are designed for quick, direct installation—ideal for field repairs or rapid assembly lines.

Looking ahead, where will aluminum screws and fasteners stand out? Picture the latest electric vehicles, drones, or smart devices—these rely on lightweight, corrosion-resistant hardware to push the boundaries of efficiency and design. Aluminum fasteners are also gaining ground in green building, marine hardware, and medical devices, where nonmagnetic, easy-to-machine, and recyclable hardware is in demand. Whether you’re specifying an alu bolt for a solar panel frame or selecting aluminum machine screws for an electronics housing, the right choice can make a real difference in performance and longevity.

Of course, there are some limitations: aluminum fasteners may gall or strip threads if over-torqued and can suffer galvanic corrosion if paired with dissimilar metals in wet environments. Always consider the full assembly context, and look for anodized or coated options when exposure is a concern. And remember, “screws for aluminum” sometimes refers to stainless or coated self-drillers designed for aluminum sheet—not just fasteners made from aluminum itself.

Ready to dive deeper? The next sections will cover torque specs, galvanic mitigation, and field-tested picks for every application.

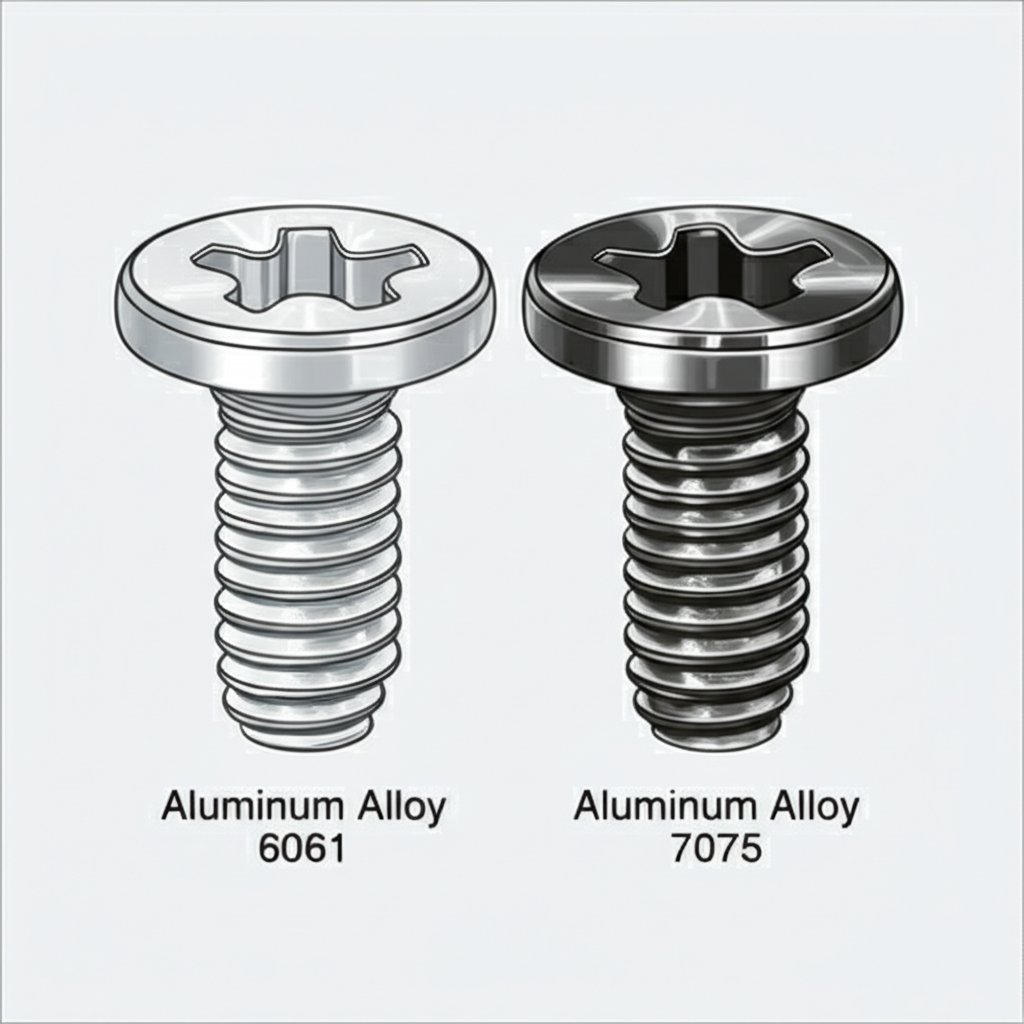

When you’re selecting aluminum bolts, screws, or nuts for your next project, you’ll quickly notice that not all aluminum fasteners are created equal. Sounds complex? Let’s break it down: the most widely used alloys for aluminum screws are 6061-T6 and 7075-T6. Each brings a distinct balance of strength, machinability, and corrosion resistance, which means your choice can make or break the performance of your assembly.

| Alloy | Temper | Tensile Strength (MPa/ksi) | Yield Strength (MPa/ksi) | Hardness (HB) | Density (g/cm³) | Notes |

|---|---|---|---|---|---|---|

| 6061 | T6 | 290 / 42 | 240 / 35 | ~95 | 2.7 | Excellent workability, good corrosion resistance, widely used for aluminum bolts and aluminum nuts and bolts |

| 7075 | T6 | 572 / 83 | 503 / 73 | ~135-150 | 2.81 | Very high strength, less corrosion resistance, notch sensitive, common in aerospace |

Imagine you’re designing a lightweight frame for a marine or automotive application. Should you pick a 6061-T6 aluminum bolt or step up to 7075-T6? Here’s the trade-off: 7075-T6 offers nearly double the tensile and yield strength of 6061-T6, making it the go-to for high-stress, weight-critical joints—think aerospace, racing, or military hardware. But, that extra strength comes at a cost. 7075-T6 is more prone to stress-corrosion cracking and is less forgiving if you need to form or weld parts. It’s also a bit denser, though both alloys remain far lighter than steel.

For most general-purpose assemblies, 6061-T6 is the sweet spot. It’s easier to machine, more affordable, and offers reliable corrosion resistance. That’s why you’ll find 6061 in everything from aluminum nuts and bolts in marine hardware to aluminum sheet metal screws for architectural and electronics applications. If your design needs to balance machinability, moderate strength, and resistance to the elements, 6061 is likely your best bet.

Ever stripped a fastener or had a joint loosen over time? The hardness of your aluminum screw or bolt matters. 7075-T6, with its higher hardness (~150 HB), can better resist wear and galling, especially in high-cycle joints or where repeated assembly is expected. However, this increased hardness can also make the threads more aggressive on softer mating materials, so pairing with compatible aluminum nuts or using steel inserts may be necessary for long-term durability.

6061-T6, while softer (~95 HB), is less likely to damage softer substrates and provides a good balance of strength and ductility. In assemblies where aluminum sheet metal screws are used—like in siding, enclosures, or lightweight frames—6061’s machinability and corrosion resistance help ensure smooth installation and long service life.

By understanding the specific strengths, weaknesses, and best-fit scenarios for each alloy, you can confidently select aluminum fasteners that meet your project’s demands—whether you’re specifying a single aluminum bolt or an entire kit of aluminum nuts and bolts. Next, we’ll move from material science to practical assembly: how to set the right torque, choose pilot holes, and get reliable performance from every fastener you install.

When you’re assembling parts with aluminum screws, how tight is tight enough? Sounds simple, but overtightening can strip threads or even snap the fastener—especially with lighter alloys. The trick is matching torque and preload to the specific screw size, head style, and whether you’re using lubrication.

| Size | Head Type | Lubed or Dry | Recommended Torque (N·m / lbf·in) | Target Preload (% of proof) | Pilot Hole (Machine Tapping) | Pilot Hole (% for Self Tapping) | Max Stack Thickness (Self Drilling) |

|---|---|---|---|---|---|---|---|

| #6-32 | Socket | Lubed | 1.2 / 10.6 | 60–70% | 0.106 in(2.69 mm) | 80–90% | 1.5 mm |

| #8-32 | Socket | Lubed | 2.0–2.5 / 18–22 | 60–70% | 0.147 in (3.73 mm) | 80–90% | 2.0 mm |

| M4×0.7 | Pan | Dry | 2.0 / 18 | 60–70% | 3.3 mm | 80–90% | 2.0 mm |

| M5×0.8 | Socket | Lubed | 5.0–6.5 / 31–35 | 60–70% | 4.2 mm | 80–90% | 3.5 mm |

| 1/4-20 | Pan | Dry | 7.0 / 62 | 60–70% | 0.228 in (5.79 mm) | 80–90% | 3.0 mm |

Ever driven a screw and watched the threads shred or felt the fastener seize mid-way? The secret is the pilot hole. For machine screws, use a drill bit that matches the core (minor) diameter of the screw. For self tapping screws for aluminum, aim for a pilot hole 80–90% of the screw’s minor diameter. This ensures the screw forms clean threads without stripping the host material.

Example: For a #8-32 self threading screw for aluminum, a 0.1360" (about 80–90% of minor diameter) pilot hole balances holding power with ease of installation Pilot hole size chart. For 1/4 self tapping screws, a 0.2188" pilot hole is typical for Type AB and B, while Type A might use the same or slightly smaller. If you’re working with self tapping screws for aluminium, always check the manufacturer’s chart for best results.

When speed is critical, self drilling screws for aluminum (sometimes called "tek" screws) are a game changer—they drill and tap in one go. But how do you pick the right one? Match the screw’s point number to your total stack thickness. For example, a #2 point is good for up to 2 mm, while a #3 or higher handles thicker stacks. Always keep the total material thickness below the rated max for your chosen screw to avoid tip wandering or incomplete thread formation.

Always validate your pilot hole and torque settings with a test joint, especially in safety-critical or production environments. Manufacturer charts and on-site testing are your best friends for reliable results.

By dialing in torque, preload, and pilot hole size for each fastener, you’ll prevent stripped threads, minimize assembly time, and get consistent, long-lasting joints—whether you’re using aluminum screws self tapping, 1/4 self tapping screws, or self drilling screws for aluminum sheet. Up next: learn how to prevent galvanic corrosion and ensure your fasteners last in mixed-metal assemblies.

Ever wondered why stainless steel screws in aluminum sometimes fail faster than expected—especially outdoors or near the coast? When you pair stainless steel screws and aluminum in the presence of moisture (like rain, salt spray, or humidity), you set up a tiny battery called a galvanic cell. Aluminum, being the less noble (more active) metal, acts as the anode and corrodes, while the stainless steel remains protected as the cathode. This process can accelerate the breakdown of aluminum around the fastener, leading to joint failure, leaks, or unsightly staining. The risk is highest when you have a large stainless steel area in contact with a small aluminum part, and when the environment is wet or salty.

Rule of thumb: Small active metal (aluminum) attached to a large noble metal (stainless) increases corrosion risk in electrolytes like water or saltwater.

Sounds complex? Not really—there are proven ways to prevent galvanic corrosion between stainless steel screws and aluminum. The goal is to block the electrical path or shield the metals from moisture. Here’s a practical checklist you can use in the field or shop:

For stainless steel screws in aluminum, always use at least one of these barriers. In high-risk environments, combine two or more for extra assurance. For example, use a nylon washer under the screw head and a dab of dielectric grease on the threads.

Choosing the right washer and sealant can make or break the longevity of your assembly. Here’s what works best for stainless screws on aluminum:

Don’t forget regular inspection and maintenance—especially in marine installations. Check joints every 6–12 months for signs of pitting, staining, or loose fasteners, and reapply coatings or replace worn isolators as needed.

By following these steps, you’ll dramatically reduce the risk of galvanic corrosion—even when using stainless steel screws and aluminum together. For critical applications, consult with a corrosion specialist or choose certified products to ensure safety and long-term performance.

Up next: We’ll map out real-world applications and show you how to select the best screws for aluminum based on environment, duty cycle, and installation needs.

When you’re building for the sea, corrosion is your biggest enemy. Aluminum screws shine here, but only if you select wisely. For boat fittings, docks, or coastal structures, always choose anodized or coated aluminum fasteners. These resist salt spray and prevent premature corrosion. Pair them with aluminum washers or nylon isolators to break the metal-to-metal contact and further reduce galvanic risk. For panels or rails, self-tapping aluminum screws allow for quick, secure mounting without pre-drilling—just be sure to avoid overtightening, which can strip threads in soft aluminum. If you’re fastening into thin sheet, self-drilling screws are ideal; check that the drill-point matches your stack thickness for a snug fit.

Ever wondered why so many electronics manufacturers use aluminum fasteners in laptops, smartphones, and enclosures? It’s not just about weight—aluminum screws are nonmagnetic, making them perfect for sensitive electronics and MRI equipment. Use pan head machine screws with conductive finishes if you need reliable grounding paths. In lightweight frames or chassis, aluminum bolts and nuts keep assemblies strong without adding bulk. When assembling circuit boards or heat sinks, select screws with a smooth, anodized finish to avoid damaging delicate components and to maximize heat dissipation. For repeated service or upgrades, opt for machine screws paired with compatible aluminum nuts to prevent thread galling and maintain reusability.

Imagine designing an electric vehicle’s battery casing or lightweight trim. Here, every gram counts, and aluminum bolts and nuts are often the best screws for aluminum assemblies. They help reduce overall vehicle weight and improve efficiency. Use thread-locking compounds or serrated flanges to maintain clamp force under vibration and thermal cycling. For trim and interior panels, aluminum wood screws or aluminium wood screws are suitable for securing composite or hybrid materials to aluminum subframes—just ensure the screw thread matches the substrate for optimal grip. In high-vibration areas, always check torque retention during maintenance cycles to prevent loosening over time.

Building exteriors and architectural panels demand both durability and aesthetics. Aluminum siding screws, when paired with compatible coatings and sealing washers, provide weather resistance and a clean finish. Always drive at controlled torque to avoid “oil canning” (visible panel distortion). For curtain walls or window frames, use flat or button head aluminum fasteners for a flush, snag-free look. Aluminum washers help distribute load and protect the finish, especially when fasteners are exposed to the elements. For wood-to-aluminum joints—think pergolas, awnings, or facade trim—aluminum wood screws or aluminium wood screws are your go-to. They offer corrosion resistance and prevent staining or streaking on visible surfaces.

Remember, for highly structural or load-bearing joints—like beams or engine mounts—steel or stainless fasteners may still be required. But for most lightweight, corrosion-prone, or aesthetic-driven assemblies, aluminum fasteners are a field-tested choice. By matching alloy, head style, and installation method to your application, you’ll get the best performance and service life from every fastener.

Next up: Learn how to maximize service life and troubleshoot aluminum fastener issues in the field, from reuse limits to common failure symptoms.

Ever wondered how many times you can safely reuse aluminum self tapping screws or other aluminum hardware before risking joint failure? Imagine you’re servicing an enclosure or reassembling a lightweight frame—should you grab the same fastener, or reach for a new one? Here’s what matters: aluminum fasteners, while corrosion-resistant and lightweight, are more susceptible to thread wear and galling than steel equivalents. For non-critical joints, you can typically reuse aluminum screws up to three times—provided the threads and heads are undamaged and remain within spec. For critical or high-torque applications, treat each aluminum screw as single-use to maximize safety and integrity.

How do you keep track of which aluminum hardware has been reused, and how often? Simple visual cues and records can save you hours of troubleshooting down the line. Try these field-proven marking practices:

For critical assemblies, consider using unique color codes or barcodes that link each fastener to its maintenance history—particularly helpful in regulated industries or high-value equipment.

Imagine you’re on-site and spot a corroded or loose fastener. What next? Here’s a quick diagnostic table to speed root-cause correction and keep your assemblies reliable:

| Symptom | Probable Cause | Immediate Action | Preventive Fix |

|---|---|---|---|

| Stripped Head | Over-torquing, worn drive, poor tool fit | Replace fastener, use correct tool | Apply correct torque, use quality drivers |

| Thread Pull-Out | Over-tightening, soft substrate, excessive cycles | Install new screw, consider insert | Limit reuses, use thread inserts for soft materials |

| Galling (Thread Seizure) | Lack of lubrication, high speed assembly | Stop, back out fastener, re-lube | Always lubricate, reduce speed, use compatible materials |

| Corrosion Staining | Galvanic reaction, moisture ingress | Clean area, replace fastener if needed | Add isolation (washers, sealants), use coated fasteners |

| Loosening Under Vibration | Insufficient preload, no locking feature | Retighten, add locking compound | Use prevailing torque nuts, threadlockers, or serrated flanges |

| Fatigue Cracking | Cyclic loading, stress concentration, improper material selection | Replace fastener, inspect surrounding area | Review joint design, use fasteners rated for fatigue |

Important: Aluminum set screws are not recommended for high-load shear applications unless validated by testing. Their lower shear strength compared to steel can lead to premature failure under side loads.

By following these serviceability and troubleshooting practices, you’ll extend the life of your aluminum hardware and reduce costly downtime. Next, we’ll look at how aluminum fasteners stack up in life-cycle cost and weight compared to steel and stainless alternatives.

When you’re deciding between aluminum screws, stainless, or steel fasteners, the numbers tell a compelling story. Imagine you’re assembling a lightweight frame, an electronics rack, or even a solar panel array. What difference does it make if you switch to bolts for aluminum instead of traditional steel?

| Example Joint | Quantity | Fastener Mass (kg) | Weight Saved (kg) | Estimated Cost Delta ($) | Payback Driver |

|---|---|---|---|---|---|

| Electronics Chassis (M5 x 16mm) | 500 |

Aluminum: 1.7g Stainless: 2.45 |

1.60 | +20 (Aluminum higher unit price) | Assembly speed, handling, EMI reduction |

| Automotive Panel (1/4" x 1" bolts) | 200 |

Aluminum: 0.44 Steel: 1.30 |

0.86 | +10 (Aluminum higher unit price) | Fuel savings, corrosion resistance |

| Solar Mounting Array (M8 x 50mm) | 150 |

Aluminum: 0.66 Steel: 1.85 |

1.19 | +15 (Aluminum higher unit price) | Maintenance, weather durability |

As shown above, switching to aluminum metric bolts or aluminum carriage bolts can reduce fastener mass by 60–70% compared to steel or stainless. This isn’t just a number on paper. In automotive and aerospace applications, every kilogram saved can lower fuel consumption, improve acceleration, and even allow for lighter supporting structures. In electronics, lighter assemblies mean easier handling and potential cost savings in shipping and installation.

Sounds complex? Here’s the real-world payoff: while the sticker price for an aluminum bolt may be slightly higher than a basic steel fastener, the return on investment (ROI) comes from three main sources:

For example, in the renewable energy sector, using aluminum bolts for mounting frames means fewer callbacks for corrosion issues and a longer service life on exposed installations. In automotive, lighter fasteners can translate directly to improved fuel economy and lower emissions. Even in machinery, the ease of machining and installation can lower labor costs and speed up assembly.

But is aluminum always the winner? Not quite. There are trade-offs you should weigh before making the switch. If your joint requires very high clamp loads, or will be exposed to temperatures above 400°F (where aluminum loses strength rapidly), a steel or stainless fastener may be the safer choice. For example, primary structural joints, engine mounts, or locations subject to repeated shock loads are best served by high-strength steel or stainless—even if it means more weight.

In summary, aluminum fasteners are a strategic choice for weight-sensitive, corrosion-prone, or high-volume assemblies where every gram and every minute count. For high-load, high-temperature, or critical safety joints, steel or stainless still hold their ground.

Key takeaway: Aluminum fasteners deliver the biggest ROI when weight, corrosion resistance, and assembly speed matter more than maximum strength. Weigh your application’s needs, and you’ll know when to make the switch.

Next, we’ll equip you with a specification toolkit to streamline procurement and ensure you get the right aluminum bolts, nuts, and screws for your project every time.

When you’re ready to source aluminum screws, clarity is your best friend. Ever sent a quote request and gotten the wrong part? It happens more often than you think—especially with so many head fastener styles, alloys, and finishes out there. To avoid costly mix-ups, a detailed Request for Quote (RFQ) is essential. Here’s a checklist you can use or adapt for your next order:

Attaching drawings or datasheets can further eliminate ambiguity. If you’re searching for “aluminum bolts near me,” include your preferred delivery location to streamline shipping options.

Sounds complex? It doesn’t have to be. Inspection requirements ensure you get reliable, safe aluminium fasteners every time. Here’s what to include in your RFQ or purchase order:

Requesting samples for fit and torque validation before bulk purchase is a smart move—especially if you’re working with a new supplier or custom aluminum nut and bolt sets.

Choosing a supplier is about more than just price. Imagine getting a shipment of aluminum screws, only to find they don’t meet your spec or lack traceability. Here’s a quick supplier vetting list:

For complex or high-volume projects, prioritize suppliers who offer a wide range of aluminium fasteners and can provide both off-the-shelf and custom solutions. Don’t hesitate to ask for references or case studies from similar industries.

Ever seen a part number like AL-6061T6-M5X16-PAN-ANOD-BLK? It’s not just a code—it’s a recipe for exactly what you need. Here’s a breakdown you can use for aluminum screws, nuts, or bolts:

| Field | Example | Description |

|---|---|---|

| Material | AL | Aluminum |

| Alloy Temper | 6061T6 | 6061 alloy, T6 temper |

| Size Thread | M5X16 | Metric 5mm diameter, 16mm length |

| Head Drive | PAN | Pan head, Phillips drive |

| Finish | ANOD-BLK | Anodized, black |

| Spec | ISO7380 | Reference standard/specification |

Customize as needed for your application. This approach works for aluminium machine screws, nuts, and other head fasteners too.

Sample spec line: AL-6061T6-M5X16-PAN-ANOD-BLK-ISO7380 — Aluminum, 6061-T6, M5 x 16mm, pan head, anodized black, ISO 7380 compliant.

By following these procurement and specification best practices, you’ll eliminate ambiguity, speed up sourcing, and ensure your aluminum fasteners arrive exactly as you expect. Next, we’ll wrap up with a step-by-step checklist and resources for building reliable aluminum assemblies.

When you reach the finish line of your project, how do you ensure your aluminum screw choices deliver the reliability and longevity you expect? Imagine you’re assembling a lightweight frame, an electronics enclosure, or an architectural facade—missing just one critical detail can lead to headaches down the road. Here’s a scannable checklist to help you lock in the best screws for aluminium assemblies every time:

Design preload and corrosion control before selecting the screw.

Sounds like a lot? When you break it down, each step helps avoid the most common pitfalls—stripped threads, premature corrosion, or mismatched hardware. Here’s how to move from planning to successful execution:

Imagine having a single partner who can guide you from design through sourcing and field support. That’s where working with a proven specialist—like Shengxin, a professional aluminum profile manufacturer in China—can make all the difference. Their expertise spans aluminum frameworks, custom finishes, and matching hardware, ensuring your assemblies are robust, attractive, and built for the long haul. Explore their capabilities and resources on aluminum screws for your next project.

By following this actionable roadmap, you’ll not only select the best screws for aluminium but also build assemblies that stand the test of time—whether you’re working with aluminum screw sets, self tappers for aluminium, or mixed-material joints using stainless steel fasteners with aluminum. Ready for your next project? Start strong with a clear plan, trusted partners, and proven best practices.

Aluminum screws are significantly lighter than steel or stainless alternatives, making them ideal for weight-sensitive projects like aerospace, electronics, and automotive assemblies. They also offer natural resistance to corrosion due to their oxide layer, are nonmagnetic, and provide good electrical conductivity. These features make aluminum screws a top choice for environments where reducing mass and avoiding rust are priorities.

Self-tapping aluminum screws are best for joining thin sheet materials where cutting threads during installation is needed, such as in aluminum panels or enclosures. Self-drilling screws are ideal for rapid assembly in multi-layer sheet stacks, as they drill and tap in a single step. Both types reduce installation time and are especially useful in field repairs or high-volume production.

To prevent galvanic corrosion in mixed-metal joints, use isolation techniques such as nylon or polymer washers, anodized coatings, or sealants to block moisture and direct metal-to-metal contact. Regular inspection and maintenance, especially in marine or humid environments, further reduce the risk of corrosion and extend the life of your assembly.

Aluminum screws are suitable for non-structural or lightly loaded joints. Their tensile strength is lower than most steel fasteners, so for high-load or primary structural connections, steel or stainless steel fasteners are recommended. Aluminum fasteners excel in applications where weight, corrosion resistance, and ease of machining are more important than maximum strength.

When sourcing aluminum screws, specify the alloy and temper (such as 6061-T6 or 7075-T6), head and drive type, finish or coating, and required torque. Choose reputable suppliers with quality certifications and request samples for fit and torque validation. For integrated solutions involving aluminum profiles and matching hardware, consider working with established manufacturers like Shengxin Aluminum for expert guidance and reliable sourcing.

serviço on-line

serviço on-line 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360