Unlock Quality: Finding Top Aluminium Profile Manufacturers in China

Ever wondered how skyscrapers, electric vehicles, and even your laptop stay so lightweight yet incredibly strong? The answer often lies in aluminium profiles—versatile components that quietly shape our modern world. But what exactly are aluminium profiles, and why are so many businesses turning to China for their supply?

What Are Aluminium Profiles?

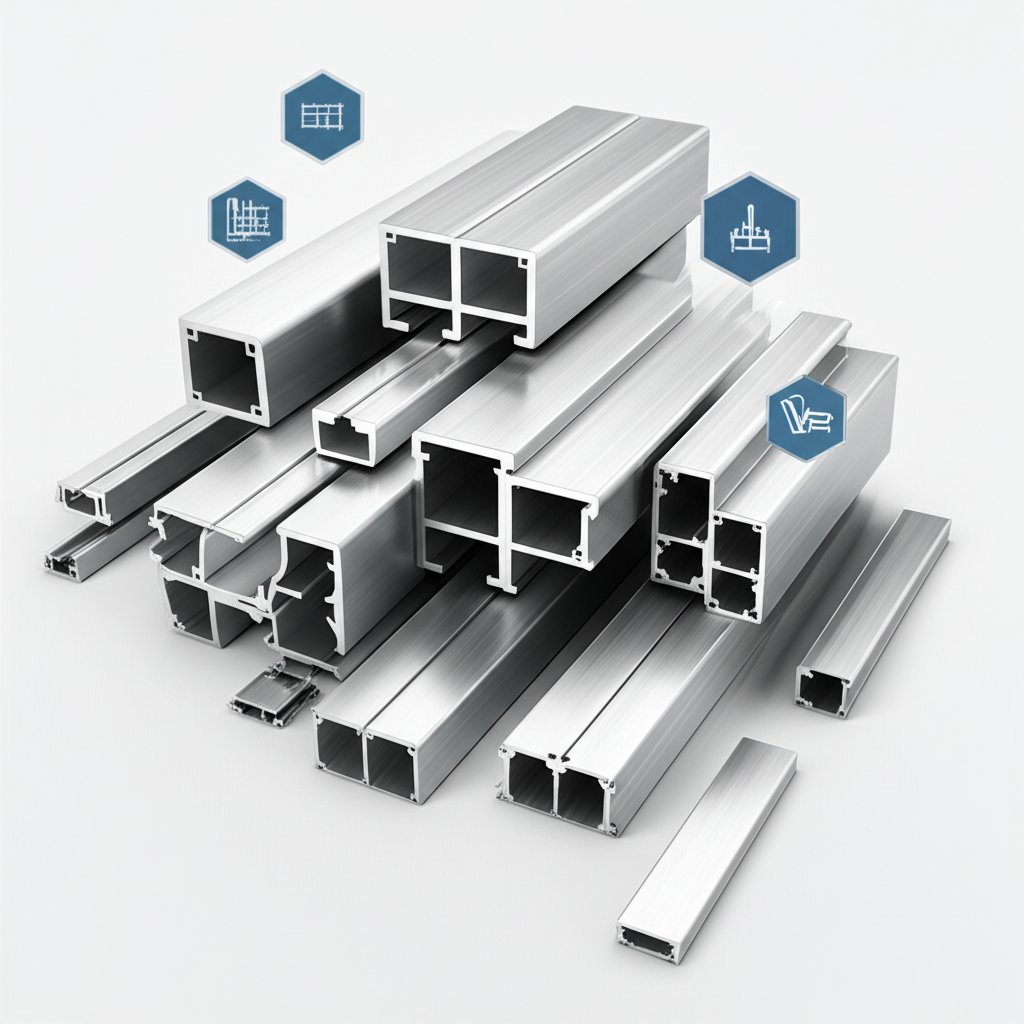

Aluminium profiles are specially shaped lengths of aluminium, created through a process called extrusion. Think of them as the backbone of countless products, from window frames and solar panel mounts to intricate parts in trains and robotics. Their unique blend of lightness, strength, and corrosion resistance makes them a go-to choice for engineers and designers across industries.

-

Lightweight & Durable: Perfect for reducing the weight of cars, planes, and buildings without sacrificing strength.

-

Corrosion Resistant: Withstands weather and chemicals, making them ideal for outdoor and industrial use.

-

Highly Customizable: Manufacturers can create profiles in virtually any shape to fit specialized needs.

Given these advantages, it’s no surprise that global demand for aluminium profiles is surging. In 2024, the market for aluminium profiles and accessories reached over $56 billion, with projections showing strong growth driven by the need for sustainable, lightweight materials in construction, automotive, renewable energy, and more (source).

Why China Is the Global Hub

So, why do so many companies source from aluminium profile manufacturers in China? The answer comes down to a powerful combination of scale, expertise, and innovation. China produces more than half of the world’s aluminium output—over 40 million metric tons annually—making it the undisputed leader in both capacity and technology (source). This dominance isn’t just about quantity; it’s also about the ability to deliver high-quality, cost-effective solutions tailored for a wide range of industries.

-

Massive Production Capacity: Ensures steady supply and competitive pricing for global buyers.

-

Advanced Manufacturing: Chinese factories invest in cutting-edge technology, enabling precise, high-performance profiles.

-

Global Reach: Efficient logistics and export expertise make China a reliable partner for businesses worldwide.

Imagine sourcing aluminium profiles for a new solar farm, a fleet of electric buses, or the next generation of smart buildings. Chances are, the profiles you need are already being produced by leading manufacturers in China, ready to be customized and shipped globally.

What You’ll Learn in This Guide

This article will walk you through everything you need to know about working with aluminium profile manufacturers in China. You’ll discover:

-

How aluminium profiles are made and why they’re so valuable

-

What makes China the world’s top supplier

-

How to source, evaluate, and partner with reliable manufacturers

-

Best practices for quality assurance and building successful long-term relationships

Ready to unlock quality and innovation for your next project? Let’s dive into the world of aluminium profiles and discover why China remains the preferred destination for businesses seeking excellence and value.

When you walk through a modern airport, open a sleek window frame, or notice the slim rails of an electric vehicle, you’re seeing the work of aluminium profile manufacturers. But what exactly are aluminium profiles, and why do so many industries rely on them?

What Are Aluminium Profiles?

Aluminium profiles are specially shaped sections made from aluminium alloys, produced primarily through a process known as extrusion. Imagine pushing soft clay through a mold to create long, uniform shapes—that’s the basic idea, but with molten aluminium and advanced machinery. These profiles can be customized to almost any cross-sectional design, making them an essential component for countless applications.

Key Properties That Make Aluminium Ideal

Why do aluminium profile manufacturers and engineers consistently choose aluminium over other metals? The answer lies in its unique combination of properties:

-

Lightweight: Aluminium’s low density (about 2.7 g/cm³) means structures are easier to handle and transport, yet still strong.

-

Corrosion Resistance: A natural oxide film forms on the surface, protecting the metal from rust and weather-related damage—even in humid environments (source).

-

High Strength-to-Weight Ratio: Provides structural integrity without adding unnecessary bulk, making it ideal for load-bearing and weight-sensitive applications.

-

Recyclability: Aluminium can be recycled repeatedly without losing its core properties, supporting sustainability goals.

-

Excellent Conductivity: Both electrical and thermal conductivity make aluminium profiles suitable for electronics and heat dissipation systems.

-

Easy Surface Treatment: Processes such as anodizing, powder coating, and painting enhance durability and appearance.

Common Applications Across Industries

Aluminium profiles manufacturers supply products that touch nearly every sector of the economy. Here’s a look at where these profiles are most commonly used:

-

Construction: Window and door frames, curtain walls, roofing, and decorative facades.

-

Automotive & Transportation: Vehicle frames, structural parts, rail transit accessories, and body panels.

-

Electronics: Heat sinks, casings for devices, and internal thermal conductors.

-

Industrial Machinery: Machine frames, conveyor systems, and assembly lines.

-

Furniture: Table legs, frames, modular furniture systems, and decorative elements.

For a deeper dive into the manufacturing capabilities and the variety of aluminium extrusion profiles available, check out this resource from a leading aluminium profiles manufacturer in China.

Popular Alloys: 6061 and 6063

Not all aluminium profiles are created equal. The alloy composition determines key characteristics like strength, corrosion resistance, and surface finish. Two of the most widely used alloys by aluminium profile manufacturers light metals are:

-

6061: Known as “structural aluminium,” it offers a great balance of strength, machinability, and weldability. It’s widely used in load-bearing structures, vehicles, and machinery where high strength is essential (source).

-

6063: Often called “architectural aluminium,” this alloy excels in extrudability and surface finish, making it perfect for windows, doors, and decorative profiles. It also provides excellent corrosion resistance and is ideal for applications exposed to the elements.

Other alloys like 5052, 7000 series, and specialized blends are also used, each tailored for specific performance needs—from marine environments to aerospace components (source).

Why Aluminium Profiles Stand Out

In summary, aluminium profiles offer a rare mix of versatility, durability, and sustainability. Whether you’re an engineer designing a new product or a business owner sourcing materials, understanding these fundamentals will help you choose the right aluminium profile manufacturer for your needs. Next, we’ll explore how these profiles are actually made—shedding light on the extrusion process that brings complex designs to life.

Ever wondered how intricate aluminium profiles go from raw metal to the sleek, customized shapes used in everything from skyscraper frames to electronics? The secret lies in the aluminium extrusion process—a marvel of engineering that makes modern manufacturing possible. If the term "aluminium profile manufacturing process" sounds complicated, don’t worry. Let’s break it down step by step so you can understand exactly how aluminium extrusion profile manufacturers create the backbone of countless industries.

Step-by-Step: The Aluminium Profile Manufacturing Process

-

Billet Preparation

The journey starts with aluminium billets—solid, cylindrical pieces made from pure aluminium or alloyed with elements like magnesium or silicon. These billets are carefully preheated to a specific temperature (usually between 400–500°C) to soften the metal without melting it, making it malleable for extrusion (source).

-

Extrusion Through the Die

The preheated billet is loaded into an extrusion press, where a powerful hydraulic ram pushes it through a steel extrusion die. The die is essentially a mold with an opening shaped to the desired cross-section of the final profile. As the metal is forced through, it takes on the exact shape of the die—imagine squeezing toothpaste through a shaped nozzle, but under thousands of tons of pressure (source).

-

Profile Emergence & Cooling

As the newly formed aluminium profile exits the die, it is still very hot. To preserve shape and mechanical properties, it’s rapidly cooled—often with fans or water sprays—along a long run-out table.

-

Stretching & Straightening

After cooling, the profile may have slight twists or bends. Special stretching machines gently pull the profile to correct any distortions, ensuring straightness and dimensional accuracy.

-

Cutting to Length

The straightened profile is then cut into specified lengths—typically between 8 and 24 feet, though custom sizes are possible. This step prepares the profiles for further processing or shipping.

-

Heat Treatment (Aging)

Many profiles undergo heat treatment to enhance their strength and durability. By placing them in ovens, manufacturers accelerate the aging process (to tempers like T5 or T6), which can significantly increase mechanical properties. For example, 6061 aluminium can achieve a tensile strength of 310 MPa after heat treatment, compared to 241 MPa when untreated (source).

-

Finishing & Fabrication (Optional)

Depending on the application, profiles may receive surface treatments such as anodizing, powder coating, or painting for enhanced appearance and corrosion resistance. Additional fabrication—like drilling, machining, or punching—can bring profiles to their final specifications.

The Critical Role of Extrusion Dies

Here’s where things get really interesting: the die. Every unique profile shape requires its own custom die, typically made from robust H13 steel to withstand immense pressure. There are three primary types of dies used by aluminium extrusion profile manufacturers:

-

Solid Dies: Create profiles with no enclosed voids (e.g., bars, angles, channels).

-

Hollow Dies: Produce shapes with enclosed spaces (like tubes or T-slots), using a mandrel and cap system.

-

Semi-Hollow Dies: For profiles with partially enclosed voids—think channels with a narrow gap.

Tooling support—like backers and bolsters—is essential to prevent die deformation and maintain precise tolerances, especially for complex or delicate shapes (source). The choice and design of the die not only determine the shape but also affect production speed, material usage, and even the lifespan of the die itself.

Why Extrusion Is the Preferred Method

So, why do so many aluminium extrusion profile manufacturers favor this process?

-

Versatility: Extrusion can produce simple bars or highly complex, multi-void shapes tailored to any application.

-

Precision: The process allows for tight tolerances and consistent quality, critical for industries like aerospace, electronics, and construction.

-

Cost-Effectiveness: Tooling is generally less expensive and faster to produce than for other metal forming methods, enabling quick prototyping and market entry (source).

-

Material Efficiency: Minimal waste is generated, and offcuts can be recycled directly back into the process.

Imagine designing a new heat sink for electronics or a custom window frame—extrusion lets you create the exact profile you need, often in a single, seamless piece.

Understanding the aluminium profile manufacturing process is key to appreciating the flexibility and quality that top manufacturers in China can deliver. Next, we’ll explore why China’s unique combination of scale, technology, and expertise makes it the world’s leading hub for aluminium extrusion profile manufacturers—and what that means for your business.

Ever wondered why so many global businesses turn to aluminium profile manufacturers in China for their most critical projects? If you’ve sourced materials before, you’ve probably noticed that China dominates this sector—supplying everything from simple window frames to high-tech rail transit components. But what gives China its edge, and why do industry leaders like Shengxin Aluminum consistently set benchmarks for quality and innovation?

The Economic and Infrastructural Edge

Imagine you’re tasked with finding a reliable, cost-effective source for large-volume aluminium profiles. China’s unique blend of economic scale, government support, and infrastructure makes it the world’s go-to hub. Here’s why:

-

Cost-Effectiveness: China’s vertically integrated supply chains and massive economies of scale drive down production costs. This enables manufacturers to offer competitive pricing, even for custom or complex profiles.

-

Massive Production Capacity: With annual output exceeding 40 million metric tons—over half of the world’s supply—China’s aluminium industry can handle orders of any size, from one-off prototypes to bulk shipments for multinational projects (source).

-

Robust Infrastructure: State-of-the-art ports, logistics networks, and industrial parks streamline the movement of raw materials and finished goods, reducing lead times and ensuring reliability for global buyers.

Advanced Technology and Innovation

China isn’t just about quantity—it’s about quality and technological leadership. Over the past few decades, the nation has invested heavily in automation, digitalization, and green manufacturing. Here’s what sets leading Chinese manufacturers apart:

-

Cutting-Edge Equipment: Companies like Shengxin Aluminum operate advanced extrusion lines—some with capacities up to 5,500 tons—enabling the production of large, complex profiles with tight tolerances and superior finishes.

-

Continuous R&D: Ongoing research has led to breakthroughs in energy-saving technologies, digital process control, and high-performance alloys. For example, digital twin and intelligent sensing systems have improved product consistency and reduced energy intensity across the industry (source).

-

Sustainability Initiatives: Many manufacturers have adopted green practices, from recycling aluminium to using hydropower and reducing emissions, aligning with global sustainability standards.

Government Support and Skilled Workforce

When you partner with aluminium profile manufacturers in China, you benefit from a supportive ecosystem built for industrial success:

-

Policy Incentives: The Chinese government provides subsidies, tax breaks, and investment in R&D to promote advanced manufacturing and environmental stewardship.

-

Skilled Labor Force: Decades of industrial growth have cultivated a workforce with deep expertise in metallurgy, engineering, and precision manufacturing—ensuring high-quality outputs at every stage.

Case in Point: Scale and Innovation at Shengxin Aluminum

Take Shengxin Aluminum as a real-world example. With over 21 years of experience, state-of-the-art facilities spanning 350,000 square meters, and 28 extrusion machines ranging from 600 to 5,500 tons, Shengxin exemplifies the scale and versatility that define top-tier Chinese manufacturers. Their investment in precision machining, custom mold development, and eco-friendly production processes demonstrates how Chinese companies are not just meeting global standards—they’re setting them (source).

China’s leadership in aluminium profile manufacturing is no accident—it’s the outcome of strategic investment, relentless innovation, and a commitment to quality at every level. As you explore common profile types and sourcing strategies in the next section, you’ll see how this unique ecosystem empowers buyers to access a world of possibilities, whether you need standard profiles or custom-engineered solutions.

When you look around a modern city—whether it’s the gleaming glass of a high-rise, the sturdy rails in a subway station, or the sleek casing of LED lights—you’re witnessing the impact of China’s aluminium profile expertise. But with so many varieties, how do you know which type fits your project? Let’s break down the most common aluminium profiles produced by leading Chinese manufacturers and see how each serves unique industries and applications.

Diverse Aluminium Profiles: From Architecture to Industry

China’s manufacturing sector offers an impressive range of aluminium profiles, each tailored for specific functions. Here’s a quick overview of the major types you’ll encounter:

-

Architectural Profiles (windows, doors, curtain walls):

-

Used by aluminium window profile manufacturers to create frames, sashes, and support structures.

-

Offer excellent strength-to-weight ratios and weather resistance, ideal for modern buildings and facades (reference).

-

Often finished with anodizing or powder coating for enhanced appearance and durability.

-

Industrial Profiles (T-slots, fencing, machinery):

-

Produced by aluminium t slot/ fencing profile manufacturers for use in modular assembly lines, workstations, safety guards, and automation equipment.

-

T-slot designs allow for flexible, bolt-together construction—think of them as the adult version of building blocks for engineers.

-

Common in robotics, conveyor systems, and protective fencing in factories (reference).

-

LED Lighting Profiles (channels, housings, heat sinks):

-

Manufactured by aluminium led profile manufacturers and led aluminium profile manufacturers to house LED strip lights.

-

Provide both heat dissipation and a sleek, finished look for lighting installations in homes, offices, and commercial spaces.

-

Available in a range of shapes—U, T, triangle, and more—to fit different lighting needs.

-

Decorative Profiles (trims, moldings, furniture):

-

Used in interior design, furniture frames, and architectural accents.

-

Can be customized in color, finish, and cross-section to match any design vision.

-

Lightweight yet strong, making them easy to install and maintain.

-

Transportation Profiles (rail transit, automotive, marine):

-

Support lightweight construction in vehicles, trains, buses, and ships.

-

Used for body frames, luggage racks, heat shields, and more (reference).

-

Help reduce overall vehicle weight for fuel efficiency and performance.

Comparing Common Aluminium Profile Types

To help you quickly identify which profile suits your needs, here’s a side-by-side comparison of three widely used types:

|

Profile Type

|

Typical Applications

|

Key Features

|

|

Architectural (Window & Curtain Wall)

|

Window frames, curtain wall mullions, door sashes

|

-

Excellent weather resistance

-

Customizable finishes (anodized, powder-coated)

-

High dimensional precision

|

|

Industrial (T-slot & Fencing)

|

Machine frames, workstations, safety barriers

|

-

Modular and easy to assemble

-

Supports rapid prototyping and reconfiguration

-

Robust for factory environments

|

|

LED Lighting

|

LED strip housings, heat sinks, architectural lighting

|

-

Efficient heat dissipation

-

Variety of shapes for different installations

-

Enhances light diffusion and fixture aesthetics

|

Customization and Innovation

One of the reasons China’s aluminium profile industry stands out is its flexibility. Manufacturers offer standard profiles as well as fully customized solutions—tailoring size, shape, alloy, finish, and even packaging to meet diverse market needs. Whether you need a unique profile for a new product launch or a reliable supply of standard T-slots, Chinese factories can deliver at scale and speed (reference).

As you explore sourcing options, remember that understanding the specific strengths of each profile type—and the capabilities of your manufacturing partner—will help you make the best choice for your project. Next, we’ll dive deeper into how to source both standard and custom profiles from the Chinese market, ensuring you get exactly what you need for your next innovation.

When you’re planning a new project—whether it’s an automated assembly line, a modern office façade, or a specialized piece of equipment—the choice between standard and custom aluminium profiles can feel daunting. How do you decide which option fits best? And what should you expect when sourcing from a leading aluminium profile section manufacturer in China?

Standard vs. Custom Aluminium Profiles: What’s the Difference?

Let’s start with the basics. Standardized aluminium profiles, such as the popular 4080 and 45mm series, are widely available and often stocked by major suppliers. These profiles have fixed cross-sections, set dimensions, and are produced in high volumes—making them cost-effective and ready for immediate shipment. For example, if you need a 45mm aluminium profile manufacturer to supply profiles for modular workstations, you’ll likely find off-the-shelf options with minimal lead time.

-

Availability: Standard profiles are usually stocked in various lengths and finishes.

-

Minimum Order Quantities (MOQs): Lower MOQs make them ideal for smaller projects or prototyping.

-

Specifications: Dimensions, tolerances, and finishes are pre-defined, ensuring compatibility with industry-standard connectors and accessories.

But what if your application requires a unique cross-section, special alloy, or specific surface treatment? That’s where custom aluminium profiles come in. Here, Chinese manufacturers shine—offering tailored solutions that bring your vision to life, from intricate architectural trims to high-strength industrial frames.

Key Considerations for Sourcing Custom Profiles

Sounds complex? It doesn’t have to be. When you engage with a custom aluminium profile section manufacturer, you’ll navigate a few essential steps:

-

CAD Design & Engineering: Start with clear technical drawings or 3D models. This ensures the manufacturer understands your exact requirements, including dimensions, tolerances, and functional features (reference).

-

Tooling & Die Costs: Creating a new extrusion die is a one-time investment. The complexity of your design influences both cost and production feasibility. Discuss die lifespan and maintenance, especially for repeat orders.

-

Lead Times: Expect a longer timeline for custom profiles. Typical stages include die creation (often 1–2 weeks), sample production, and full-scale manufacturing (which can take 2–4 weeks depending on order size and complexity).

-

Prototyping: Reliable suppliers provide samples for approval before mass production. This is your chance to verify dimensions, fit, and finish.

-

Finishing Options: Choose from anodizing, powder coating, PVDF, wood grain, or custom colors. Surface treatments not only enhance appearance but also improve corrosion resistance and durability (reference).

-

Order Quantities: MOQs for custom profiles are typically higher than for standard ones, but many manufacturers offer flexible solutions for both small and large projects.

What Sets Top Chinese Manufacturers Apart?

Imagine needing a complex, heavy-duty profile for a robotics platform or a sleek, matte-finished trim for a high-end kitchen. Leading Chinese suppliers—like Shengxin Aluminum—bring advanced capabilities to the table. With large extrusion presses (up to 5,500 tons), CNC machining centers, and a suite of finishing lines, they can deliver everything from robust 4080 or 45mm aluminium profiles to intricate, custom-engineered sections for demanding industries (reference).

-

Advanced Equipment: Large presses enable the production of oversized or complex profiles with consistent quality.

-

Precision CNC Processing: Allows for tight tolerances, custom cuts, and secondary fabrication—ideal for specialized machinery or architectural elements.

-

Flexible Production: Whether you need a single prototype or a bulk shipment, leading manufacturers adjust capacity and scheduling to meet your needs.

-

Comprehensive Quality Control: Dedicated teams inspect each batch for compliance with international standards, ensuring reliability from sample to shipment.

How to Get Started: Practical Steps

Ready to source your next aluminium profile? Here’s a quick checklist to streamline the process:

|

Step

|

Action

|

|

1. Define Requirements

|

List dimensions, tolerances, alloy, and surface finish.

|

|

2. Select Supplier

|

Research experience, production capacity, and certifications.

|

|

3. Request Quote

|

Include technical drawings and estimated order volume.

|

|

4. Approve Sample

|

Review prototype for accuracy before full production.

|

|

5. Confirm Order

|

Agree on lead times, payment terms, and shipping details.

|

Whether you’re sourcing standardized profiles for a quick turnaround or developing a custom section for a groundbreaking design, China’s aluminium profile manufacturers offer a unique blend of scale, flexibility, and technical expertise. In the next section, we’ll explore practical strategies for finding and evaluating the right supplier—so you can move forward with confidence and clarity.

When you’re tasked with sourcing aluminium profiles for a new project, the sheer number of options in China can feel overwhelming. Where do you start? How do you separate trustworthy aluminium profile manufacturer & suppliers from the rest? Let’s break down practical, proven strategies—so you can move from uncertainty to confidence in your supplier search.

Where to Find Reliable Aluminium Profile Suppliers

Imagine you need a partner who can deliver both quality and consistency. Here are the main channels you’ll want to explore:

-

Online B2B Platforms: Sites like Alibaba, Made-in-China, and Global Sources connect you directly with thousands of suppliers. These platforms offer detailed company profiles, product catalogs, and customer reviews—making it easier to compare options side by side (reference).

-

Industry Directories: Specialized directories and sourcing websites (such as Sourcifychina.com) often vet their listed suppliers, providing an extra layer of credibility. You’ll find filters for certifications, production capacity, and export history (reference).

-

Trade Shows & Expos: Events like the China Import and Export Fair (Canton Fair) or Aluminium China Expo are invaluable for meeting multiple suppliers face-to-face, inspecting products firsthand, and negotiating terms in real time. Many buyers use these events to build relationships and discover new market trends.

-

Industry Associations: Membership in organizations such as the China Nonferrous Metals Industry Association signals a commitment to quality and industry standards. These associations often publish lists of reputable manufacturers and offer dispute resolution channels.

-

Referrals & Business Networks: Recommendations from industry peers, existing partners, or even third-party sourcing consultants can shortcut your research. Trusted referrals often come with candid feedback about reliability and service.

-

Sourcing Agents: Local agents or procurement companies act as intermediaries, helping you vet suppliers, negotiate contracts, and manage logistics.

Pros:

Deep market knowledge, language/cultural expertise, and hands-on quality checks.

Cons:

Additional fees, potential conflicts of interest, and less direct control over communications.

How to Filter and Evaluate Potential Suppliers

Once you’ve gathered a list of potential aluminium profile manufacturer & suppliers, it’s time to narrow the field. Here’s a step-by-step approach:

-

Check Company Background: Use platforms like qcc.com (for Chinese business registration info) or importyeti.com (for export records) to verify company legitimacy and track record (reference).

-

Review Certifications: Look for ISO 9001 (quality management), ISO 14001 (environmental management), and relevant product certifications. These signal a commitment to international standards.

-

Request Product Samples: Before making any commitment, ask for samples to evaluate quality, finish, and adherence to your specifications. This step is crucial for both standard and custom profiles.

-

Assess Communication: Pay attention to response times, clarity, and willingness to answer technical questions. A responsive supplier is more likely to provide good after-sales support.

-

Read Customer Reviews: Seek out independent testimonials and case studies. Positive feedback from similar industries or international clients is a strong endorsement.

-

Compare Pricing and Terms: Don’t be tempted by the lowest price alone—balance cost with quality, lead time, payment terms, and after-sales service.

-

Consider a Factory Visit or Virtual Tour: If possible, visit the facility or request a video walkthrough to see production capacity, quality control processes, and working conditions firsthand.

Quick Checklist: Narrowing Down Your Supplier List

|

Step

|

What to Look For

|

|

Company Verification

|

Valid registration, export history, industry affiliations

|

|

Certifications

|

ISO 9001, ISO 14001, product-specific standards

|

|

Sample Evaluation

|

Meets technical specs, finish quality, packaging

|

|

Communication

|

Timely, clear, technically competent responses

|

|

Customer Feedback

|

Positive reviews, references, repeat clients

|

By following these strategies, you’ll transform a daunting supplier search into a focused, step-by-step process—helping you identify the right aluminium profile manufacturer & suppliers for your unique needs. In the next section, we’ll dig deeper into the due diligence and evaluation criteria that ensure you choose a partner who delivers on quality, reliability, and long-term value.

When you’re ready to move from a shortlist to a final decision, how do you ensure the aluminium profile manufacturer you choose in China will deliver on quality, reliability, and value? Imagine investing months into a project, only to discover your supplier can’t meet your standards or deadlines. To avoid costly missteps, it’s essential to apply a thorough, structured vetting process—one that goes beyond a glossy website or a quick email exchange.

What Should You Look For in Aluminium Profile Manufacturers?

Picture yourself reviewing two promising suppliers. They both have attractive catalogs and competitive prices. But how do you dig deeper to uncover which partner is truly equipped to meet your needs? Here’s a practical checklist of due diligence criteria that can help you filter out risks and select a trustworthy supplier:

-

Company Background & Legitimacy: Verify business registration, operating license, and export history using official databases like qcc.com. Confirm the legal name and registration number match all documents and contracts (reference).

-

Certifications & Compliance: Look for ISO 9001 (quality management), ISO 14001 (environmental management), and other relevant industry certifications. These indicate adherence to international standards and a commitment to quality (reference).

-

Production Capacity: Assess monthly tonnage, number of extrusion lines, and ability to scale. Ask about recent upgrades, in-house finishing (like anodizing or powder coating), and CNC machining capabilities.

-

Quality Control Systems: Inquire about inspection protocols at every stage—raw material, in-process, and finished goods. Request documentation of quality procedures and sample test reports.

-

Research & Development (R&D): Does the manufacturer invest in new product development, innovative alloys, or process improvements? Strong R&D signals a forward-thinking partner who can support evolving requirements.

-

Communication & Responsiveness: Evaluate how quickly and clearly the supplier responds to technical questions, quote requests, and sample feedback. Reliable communication minimizes misunderstandings and delays.

-

Customer Reviews & References: Seek testimonials from international clients or case studies on similar projects. Ask for direct references and check independent reviews for red flags.

-

Financial Stability: Request audited financial statements or credit references—especially for large or long-term contracts. Financially stable suppliers are less likely to default or disrupt your supply chain (reference).

-

Lead Times & Delivery Performance: Review average production and shipping timelines. Ask about on-time delivery rates and backup plans for handling urgent or high-volume orders.

-

Pricing & Terms: Compare not just the quoted price, but also payment terms, deposit requirements, and any hidden costs (tooling, packaging, shipping, duties). Clarify all terms in a bilingual contract to avoid disputes.

Supplier Evaluation Checklist: A Practical Tool

To keep your vetting process organized, use a supplier evaluation checklist. Here’s a sample structure you can adapt for your own needs:

|

Criteria

|

Questions to Ask

|

|

Company Registration

|

Is the license valid and matches the contract?

|

|

Certifications

|

ISO 9001, ISO 14001, product-specific certificates?

|

|

Production Capacity

|

Monthly tonnage, number of extrusion lines?

|

|

Quality Control

|

What are the inspection procedures and frequency?

|

|

R&D Capability

|

Is there evidence of product innovation?

|

|

Communication

|

Response time, clarity, English proficiency?

|

|

Customer References

|

Are there positive reviews or case studies?

|

|

Financial Stability

|

Audited reports, credit references available?

|

|

Lead Times

|

What’s the average production and delivery time?

|

|

Pricing & Terms

|

Are all costs and payment terms transparent?

|

Score each supplier against your priorities—whether it’s quality, speed, or cost—to make an objective, data-driven decision.

Red Flags and Final Checks

Before signing a contract, watch out for warning signs: incomplete documentation, inconsistent information, reluctance to provide samples or references, or evasive answers about quality control. If possible, visit the factory or arrange a third-party audit for added assurance (reference).

By focusing on these critical criteria, you’ll dramatically increase your chances of partnering with an aluminium profile manufacturer that delivers the quality, consistency, and reliability your business demands. In the next section, we’ll explore best practices for quality assurance—so you can move from contract signing to successful project delivery with confidence.

When you’re sourcing from an aluminium alloy profile manufacturer in China, how can you be sure every shipment meets your expectations? Imagine investing in a custom profile, only to discover dimensional errors or surface flaws upon delivery. The stakes are high—so let’s break down how you can safeguard quality from the drawing board to your final product.

Start with Clear Quality Agreements and Material Specifications

Sounds obvious, but the foundation of any successful order is a detailed, written quality agreement. This document should spell out:

-

Material Specs: Specify the exact aluminium alloy (e.g., 6063-T5), temper, and any required certifications.

-

Dimensional Tolerances: Define critical measurements and acceptable variances—especially for profiles used in structural or high-precision applications.

-

Surface Finish: Detail requirements for anodizing, powder coating, or other treatments (including color, thickness, and roughness).

-

Performance Standards: Reference international norms (such as EN, ASTM, or GB standards) relevant to your application.

-

Packaging and Labeling: Outline protective packaging, labeling, and any special handling instructions.

By aligning on these details up front, you reduce the risk of misunderstandings and set a clear benchmark for quality inspections later in the process.

Inspection Stages: Ensuring Quality at Every Step

Quality assurance isn’t a one-time event—it’s a series of checks woven throughout production. Here’s how leading manufacturers structure their inspection process (reference):

-

Pre-Production (Raw Material) Inspection

-

Verify alloy composition and purity through chemical analysis.

-

Check billets for visible defects (cracks, corrosion, dirt).

-

Review supplier certificates and test reports for each batch.

-

In-Process (Extrusion & Fabrication) Inspection

-

Monitor extrusion parameters (temperature, pressure, speed) to prevent warping or dimensional errors.

-

Continuously check profile dimensions using calipers, micrometers, or laser devices.

-

Visually inspect surface quality for scratches, dents, or discoloration.

-

Assess coating consistency and thickness if surface treatments are applied.

-

Final Inspection & Mechanical Testing

-

Perform tensile, hardness, and impact tests to verify mechanical properties.

-

Conduct a thorough review of finished profile dimensions and appearance.

-

Inspect packaging and labeling before shipment.

Each stage should be documented—traceability ensures that any issues can be traced back to their source, enabling swift corrective action.

The Role of Third-Party Inspections and Communication

For international buyers, independent third-party inspections add an extra layer of confidence. These agencies can:

-

Audit factory quality systems and certifications (such as ISO 9001).

-

Conduct on-site inspections at key stages (pre-shipment, during production).

-

Provide unbiased reports with photos, test results, and compliance checks.

Effective communication is just as critical. Schedule regular updates, request progress photos, and clarify any concerns immediately. Many quality issues stem from assumptions—so keep channels open and confirm details in writing.

Handling Defects, Disputes, and Continuous Improvement

Even with robust systems, occasional defects can occur. Here’s how to handle them constructively:

-

Define Defect Categories: Agree on what constitutes a critical, major, or minor defect, and set acceptable thresholds.

-

Establish a Resolution Process: Outline steps for reporting, investigating, and resolving defects—including timelines for corrective action and replacement shipments.

-

Emphasize Root Cause Analysis: Encourage your supplier to identify and address the underlying cause, not just the symptoms (reference).

-

Promote Continuous Improvement: Periodically review quality performance and suggest process enhancements—whether it’s better operator training, updated work instructions, or new inspection tools.

By following these best practices, you’ll notice fewer surprises, smoother deliveries, and a stronger partnership with your aluminium alloy profile manufacturer. Next, we’ll wrap up with a summary of key takeaways and a look at how to unlock long-term value by working with top Chinese suppliers.

When it comes to sourcing aluminium profiles for your next big project, the journey can feel overwhelming. But as you’ve seen throughout this guide, partnering with the top aluminium profile manufacturers in China brings a wealth of advantages that can set your business apart—whether you’re building a skyscraper, upgrading your production line, or innovating in the automotive or electronics sector.

Why Choose the Best Aluminium Profile Manufacturers in China?

Imagine you need a supplier who can deliver not just on price, but on quality, reliability, and technical innovation. China’s leading manufacturers stand out in several crucial ways:

-

Unmatched Scale and Capacity: With the world’s largest production lines and vertically integrated supply chains, Chinese suppliers can handle orders of any size—offering both standard and highly customized solutions (reference).

-

Advanced Technology and Customization: Top manufacturers invest in state-of-the-art equipment, precision CNC machining, and R&D—making it possible to create profiles for the most demanding applications, from rail transit door beams to energy-efficient curtain walls.

-

Cost-Effectiveness: Competitive pricing, driven by economies of scale and local raw material availability, means you get more value without compromising on quality.

-

Stringent Quality Control: International certifications and robust inspection processes ensure every batch meets global standards for safety, performance, and durability.

-

Global Export Experience: Decades of export expertise and efficient logistics networks make Chinese suppliers reliable partners for on-time, hassle-free delivery worldwide.

Keys to Successful Partnerships: Research, Due Diligence, and Communication

Of course, unlocking these benefits depends on doing your homework. The best aluminium profile manufacturers in China are those who meet your project’s unique needs and exceed your expectations. Here’s how to make the most of your sourcing journey:

-

Conduct Thorough Research: Use multiple channels—B2B platforms, trade shows, and industry directories—to identify reputable suppliers.

-

Vetting and Evaluation: Check company credentials, certifications, production capacity, and customer reviews. Use a structured checklist to compare options objectively.

-

Clear Communication: Set out detailed specifications, quality standards, and delivery timelines upfront. Regular updates and transparent feedback loops help avoid misunderstandings.

-

Quality Assurance: Implement robust inspection protocols, consider third-party audits, and address any issues promptly for continuous improvement.

Partnering with Industry Leaders: Shengxin Aluminum as a Model

When looking for a supplier that truly exemplifies these strengths, Shengxin Aluminum stands out. As one of the top aluminium profile manufacturers in China, Shengxin’s vast production capabilities, technological innovation, and proven performance—especially in high-stakes sectors like rail transit—make them a benchmark for excellence. Their ability to deliver both standard and custom-engineered solutions, backed by international certifications and a commitment to sustainability, showcases what’s possible when you work with an industry leader.

"Choosing the right supplier isn’t just about price—it’s about building a partnership that supports your vision, ensures quality, and delivers long-term value."

As you move forward, remember to apply the best practices outlined in this guide: research diligently, vet thoroughly, communicate clearly, and never compromise on quality assurance. By doing so, you’ll unlock the full potential of what the Chinese aluminium profile industry has to offer—ensuring your projects succeed today and into the future.

Ready to take the next step? Explore top-tier suppliers like Shengxin Aluminum and discover how the right partnership can transform your business. The journey to quality, innovation, and value starts with a single, well-informed decision.

1. What makes China a global leader in aluminium profile manufacturing?

China leads due to its massive production capacity, advanced technology, and cost-effective manufacturing. Government support, a skilled workforce, and robust infrastructure enable Chinese manufacturers to deliver high-quality aluminium profiles for diverse industries worldwide.

2. How can I ensure the quality of aluminium profiles from Chinese suppliers?

Start with clear material and quality specifications in your contract. Choose manufacturers with ISO certifications, request product samples, and consider third-party inspections during production. Leading suppliers like Shengxin Aluminum maintain strict quality control systems and international standards.

3. What types of aluminium profiles are commonly produced in China?

Chinese manufacturers offer a wide range including architectural profiles (windows, doors, curtain walls), industrial T-slot profiles, LED lighting channels, decorative trims, and transportation components. Both standard and custom profiles are available to meet specific project needs.

4. What is the process for sourcing custom aluminium profiles from China?

Sourcing custom profiles involves sharing detailed CAD designs, discussing tooling and die costs, approving samples, and selecting finishing options. Top manufacturers, such as Shengxin Aluminum, provide advanced extrusion and CNC machining to deliver tailored solutions for complex requirements.

5. Why should I consider Shengxin Aluminum as a supplier?

Shengxin Aluminum is a top aluminium profile manufacturer in China with over 100 production lines, large-scale extrusion capabilities up to 5,500 tons, and a strong record in sectors like rail transit. Their expertise in both standard and custom profiles, along with international certifications, ensures quality and reliability.

serviço on-line

serviço on-line 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360