Ever wondered exactly at what temperature does aluminum melt? Whether you're working in manufacturing, metalworking, or just curious about materials science, knowing this number is fundamental. Let's get straight to the answer:

The melting point of pure aluminum is 660.32°C (1220.58°F).

This precise value is recognized worldwide as the standard for pure, unalloyed aluminum. You'll often see this figure referenced in technical datasheets, engineering standards, and scientific literature. If you've ever asked, what is the melting temperature of aluminum or what's the melting point of aluminum, this is the number you need to remember.

Sounds simple, right? But here's where things get interesting: in real-world industrial settings, pure aluminum is rarely used on its own. Instead, most aluminum products are made from alloys—mixtures of aluminum with other elements like silicon, magnesium, or copper. These added elements change how the metal behaves, especially when it comes to melting.

Why does this matter? If you're casting, welding, or heat-treating aluminum, knowing the melting temp of aluminum is just the starting point. For alloys, understanding the full melting range is crucial for avoiding defects and achieving the right material properties.

For a deeper dive into what is the melting point of aluminum, how it compares with other metals, and why this matters for your projects, check out this detailed guide: What is the Melting Point for Aluminum? Properties, Comparisons, and Industrial Insights.

As we continue, you'll discover why the melting behavior of aluminum alloys is more complex—and more important—than you might expect.

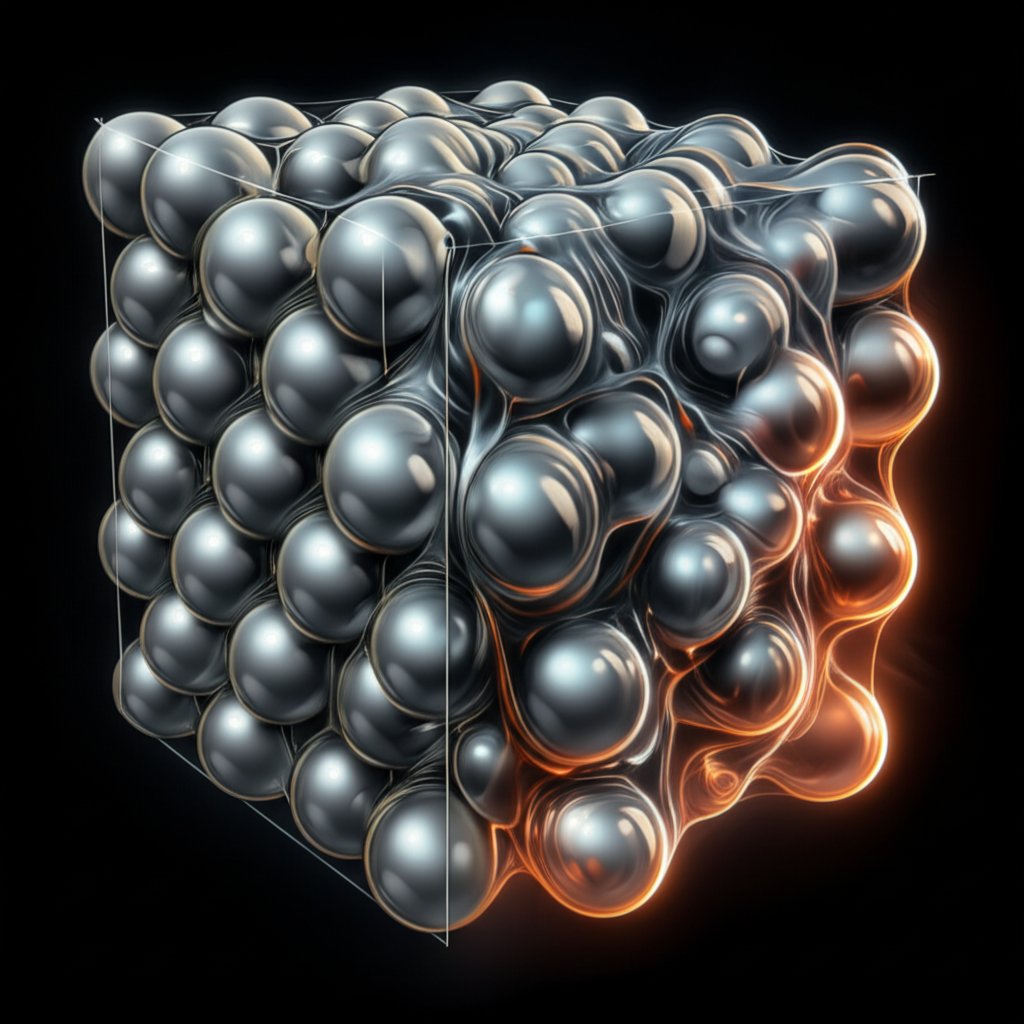

Have you ever wondered what really happens when aluminum melts? Let’s start with the basics: is aluminum a metal? Absolutely. Like all metals, aluminum is made up of atoms arranged in a highly ordered, repeating pattern called a crystal lattice. These atoms are held together by metallic bonds—think of them as a sea of electrons that glue the atoms in place, giving metals their strength, electrical conductivity, and unique shine.

When you heat a piece of aluminum, you’re adding energy to its atoms. At first, this energy just makes the atoms vibrate faster, but they’re still locked in their positions. As the temperature climbs toward the melting temp of aluminum, these vibrations become more intense. Eventually, the energy is high enough to break the metallic bonds holding the atoms in the lattice. That’s when the solid structure collapses, and aluminum transitions to a liquid state.

It’s a bit like shaking a box of magnets: at first, they stick together, but with enough force, they break apart and move freely.

Here’s where it gets even more interesting. When aluminum reaches its melting point, you might expect the temperature to keep rising steadily. But in reality, the temperature stops increasing until all the solid has turned into liquid. This is because the energy you add during this stage isn’t raising the temperature—it’s being used to break the atomic bonds. This extra energy is known as the Latent Heat of Fusion.

For aluminum, the latent heat of fusion is about 396 kJ/kg (Engineering Toolbox). That’s the amount of energy required to change one kilogram of solid aluminum into liquid at its melting temperature, without raising the temperature itself.

To define melting temperature: it’s the specific temperature at which a solid becomes a liquid under normal atmospheric pressure. For pure aluminum, this is a sharp value, but for alloys, as you’ll see in the next section, things get more complex.

Now that you know what happens at the atomic level when aluminum melts, let’s explore why alloys don’t melt at a single temperature—and what that means for real-world manufacturing.

When you’re working with aluminum or aluminium in real-world manufacturing, you might be surprised to find that most alloys don’t melt at a single, sharp temperature like pure aluminum does. Instead, they have a melting range. But why is that?

Imagine you’re heating up an aluminum alloy for casting or welding. You’ll notice it doesn’t instantly transform from solid to liquid at one precise temperature. Instead, it gradually softens and becomes partially liquid before it’s fully molten. This happens because alloys are mixtures—blends of aluminum with other elements (like silicon, copper, magnesium, or zinc)—and these different atoms disrupt the neat, orderly crystal structure of pure aluminum. As a result, the melting behavior changes.

To describe this process, metallurgists use two key terms:

Between these two points, the alloy is in a "mushy" or semi-solid state—part solid, part liquid. This is known as the melting range. For most alloys, the difference between solidus and liquidus can be anywhere from a few degrees to several dozen degrees Celsius or Fahrenheit.

Why does this matter for fabricators? The answer lies in how alloys behave during heating and cooling. The aluminum alloy melting temperature (or more accurately, the melting range) directly affects how the metal flows, fills molds, and solidifies. For instance:

It’s also important to note that not all alloys behave the same. Some special compositions—called eutectic alloys—can have a single melting point, but most commercial aluminum alloys do not. This is why the phrase aluminum alloy melting temperature or aluminium alloy melting temperature almost always refers to a range, not a single value.

Curious about the "mushy" state? Picture this: if you’ve ever seen a demonstration where a metal melts in your hand (using low-melting alloys), you’re witnessing a rapid transition through the solidus-liquidus range. For aluminum alloys, this range is higher and less dramatic, but the underlying science is the same.

Whether you call it aluminum or aluminium, the science remains the same. However, terminology can affect international specifications and communication. In North America, "aluminum" is used, while "aluminium" is common in Europe and other regions. When comparing aluminum vs aluminium or discussing aluminium vs aluminum alloys, always check the relevant standards for melting range data.

In summary, understanding the melting range—defined by solidus and liquidus temperatures—is essential for anyone working with aluminum alloys. It explains why alloys don’t behave like pure metals and why precise temperature control is critical in every stage, from casting to welding. Up next, we’ll break down the actual melting ranges for the most common aluminum alloys so you can make informed decisions in your next project.

When you’re selecting aluminum for a project—whether it’s alu sheets for construction, 4 x 8 aluminium sheets for fabrication, or aluminum powder for additive manufacturing—the exact melting behavior matters. Unlike pure aluminum, alloys have a melting range defined by their solidus and liquidus temperatures. To help you compare at a glance, here’s a detailed table covering the most popular aluminum alloys, their melting ranges, and where you’ll find them in use.

| Alloy Series/Designation | Solidus Temp (°C/°F) | Liquidus Temp (°C/°F) | Primary Applications |

|---|---|---|---|

| 6061-T6 | 582°C / 1,080°F | 652°C / 1,205°F |

Bicycle frames, automotive parts, structural components, 4/0 aluminum wire, marine fittings |

| 7075-T6 | 477°C / 890°F | 635°C / 1,175°F | Aerospace parts, high-performance sporting goods, military components |

| 5052-H32 | 607°C / 1,125°F | 650°C / 1,202°F | Marine equipment, boat hulls, fuel tanks, pressure vessels |

| 3003-H18 | 643°C / 1,189°F | 655°C / 1,211°F | Cooking utensils, storage tanks, heat exchangers, beverage cans |

| 1100 | 643°C / 1,189°F | 657°C / 1,215°F |

Food packaging, heat sinks, household items, flexible alu sheets |

Actual melting ranges may vary slightly based on specific alloy composition and product form.

Let’s break down why these numbers matter. For instance, the 6061 aluminum melting point isn’t a single value—instead, the alloy starts to soften at 582°C (1,080°F) and is fully liquid at 652°C (1,205°F). This melting range is crucial when you’re welding, casting, or extruding, because heating above the solidus but below the liquidus puts the alloy in a semi-solid state. For melting temperature of aluminum 6061 parts, this range ensures enough workability without risking total liquefaction—ideal for processes demanding precise temperature control.

Similarly, 7075-T6 is prized for its high strength-to-weight ratio, but its lower solidus (477°C/890°F) means it requires even more careful handling during heat-based fabrication. For marine or chemical environments, 5052-H32 stands out due to its higher corrosion resistance and a solidus well above 600°C, making it a top choice for alu sheets in demanding settings.

Understanding these melting ranges is also key for recycling and remelting operations. When producing cast aluminum components, knowing the cast aluminum melting point helps optimize furnace temperatures for energy efficiency and product quality.

In summary, the melting range of each alloy isn’t just a technical detail—it’s a practical guide for everything from choosing alu sheets for construction to producing high-performance 4/0 aluminum wire for electrical systems. By consulting detailed tables like the one above, engineers and fabricators can select the right alloy for their needs, ensuring optimal results in every application.

Next, we’ll look at how impurities and recycled content can further influence these melting behaviors, and what that means for quality control in modern aluminum manufacturing.

Ever wondered why two batches of aluminum might behave differently during melting, even if they’re labeled with the same alloy number? The answer often comes down to impurities—those tiny traces of elements that sneak into the metal during production or recycling. While the melting temp of aluminum is well defined for pure and alloyed forms, impurities can shift this number and change how the metal responds to heat.

In both primary and secondary (recycled) aluminum, impurities like iron (Fe), silicon (Si), copper (Cu), magnesium (Mg), and zinc (Zn) are common. These elements don’t just sit quietly—they actively influence melting behavior by interacting with the aluminum matrix, forming new phases or compounds with their own unique properties.

These impurities are especially significant in recycled aluminum, where scrap from various sources is remelted together. Even small shifts in composition can have a big impact on the final product’s properties.

Recycling aluminum is a sustainability win, but it comes with its own set of challenges for fabricators. During aluminium recycling, impurities accumulate more readily than in primary production. That’s why recycled aluminum often has a broader melting range and a slightly lower melting point than high-purity metal. This can affect everything from casting performance to mechanical properties.

Let’s look at how these changes play out in practice:

Another aspect to consider is the presence of non-metallic inclusions, such as oxides. For example, the melting temperature of alumina (aluminum oxide) is much higher than that of metallic aluminum—over 2,000°C. While these oxide inclusions don’t melt during standard fabrication, they can weaken the metal matrix and affect surface quality. High alumina density inclusions are especially problematic for applications demanding flawless finishes or high mechanical strength (Aluminium Guide).

Controlling impurity levels is thus critical—not just for maintaining the expected aluminum density and mechanical properties, but also for ensuring predictable melting behavior. Whether you’re working with new or recycled aluminum, understanding the influence of impurities helps you make informed choices at every stage of fabrication.

Next, we’ll see how aluminum’s melting point stacks up against other industrial metals—and why these differences matter for your process planning and material selection.

When planning a fabrication project, it’s natural to ask: how does the melting temp of aluminum stack up against other common metals? Imagine you’re choosing materials for casting, welding, or high-temperature applications. The melting point isn’t just a number—it tells you how much heat and energy you’ll need, what equipment is suitable, and even which manufacturing processes are possible. Let’s break down the data for the metals you’ll encounter most often.

| Metal | Typical Melting Point/Range (°C) | Typical Melting Point/Range (°F) | Key Takeaway |

|---|---|---|---|

| Aluminum (Pure) | 660 | 1220 | Low energy to melt, ideal for extrusion and casting |

| Aluminum Alloys | 463–671 | 865–1240 | Melting range depends on composition; used for versatility |

| Carbon Steel | 1371–1593 | 2500–2900 | High melting temp; requires specialized furnaces |

| Stainless Steel | 1510 | 2750 | Even higher melting point; excellent for heat-resistant parts |

| Copper | 1084 | 1983 | High copper melting point; perfect for electrical and plumbing uses |

| Iron (Wrought) | 1482–1593 | 2700–2900 | Durable, but needs high temperatures to process |

| Titanium | 1670 | 3040 | Extremely high melting point of titanium; best for aerospace and medical components |

| Brass (Yellow) | 905–932 | 1660–1710 | Brass melting point varies; used in decorative and fitting applications |

| Gold | 1063 | 1945 | High gold melting point; valued for jewelry and electronics |

| Lead | 328 | 621 | Low lead melting point; easy to cast, but limited by toxicity |

Ranges reflect typical values for commercial grades; specific alloys may vary.

Let’s put these numbers into a real-world context. Aluminum’s relatively low melting point (660°C/1220°F) means it can be melted and shaped using less energy than iron or steel. This is why it’s so popular for casting, extrusion, and recycling. In contrast, the melting temp of steel (especially stainless and carbon steels) is much higher—so high, in fact, that specialized furnaces and more robust tooling are required to process it.

Materials like titanium and stainless steel, with their extremely high melting points, are reserved for demanding environments such as jet engines, medical implants, or chemical processing equipment. On the other end of the spectrum, metals like lead and brass melt at much lower temperatures, making them easy to cast but unsuitable for high-heat applications.

Understanding these differences is key when selecting a metal for your next project. If you need a material that’s easy to melt and shape, aluminum or brass may be your best bet. If durability at extreme temperatures is a priority, materials like stainless steel or titanium should be considered—even though they require more advanced equipment.

In summary, knowing the melting point of steel, copper melting point, and how they compare to aluminum helps you select the right metal for the job and plan your fabrication process efficiently. In the next section, we’ll tie these melting behaviors back to real-world manufacturing, showing how they affect casting, welding, and extrusion in everyday production.

Imagine you’re pouring aluminum molten from the furnace into a mold. The al melting point isn’t just a trivia fact—it’s the key to whether your final casting will be flawless or riddled with defects. Because aluminum and its alloys melt over a range, not a single temperature, the way you manage the transition from solid to liquid affects everything from mold filling to the integrity of the finished part.

In short, precise control of the melting temp of aluminum isn’t optional—it’s essential for producing castings with strong, consistent properties.

When it comes to welding aluminum alloys, the melting range introduces unique hurdles. As you heat the joint, both the base metal and filler pass through the semi-solid phase. This can lead to a phenomenon called hot tearing—cracks that form as the metal contracts and solidifies unevenly.

For fabricators, understanding the exact aluminum alloy melting temperature range means fewer reworks and higher-quality joints, especially in demanding applications like aerospace or automotive construction.

Extruding alumini profiles—think window frames, heat sinks, or structural supports—demands a fine balance between temperature and pressure. If the billet isn’t heated enough, it won’t flow through the die; if it’s too hot and enters the mushy zone, surface defects and dimensional inaccuracies can result.

In all these processes, the science behind the melting temp of aluminum translates directly into better products and more efficient manufacturing. Whether you’re casting, welding, or extruding, a deep understanding of melting behavior is your best tool for achieving consistent, high-performance results.

Next, we’ll explore how sourcing the right aluminum—tailored to your project’s needs—can make all the difference in final product quality and reliability.

When it comes to choosing the right aluminum for your project, the details matter. Imagine investing in a large-scale architectural build, a fleet of vehicles, or a precision electronics component—would you risk it all on materials with unknown performance? Understanding the precise melting temp of aluminum and, just as importantly, the melting range of alloys is the foundation for success in fabrication and engineering. But how do you ensure the aluminum you purchase truly meets your needs?

For projects demanding specific thermal performance and predictable results, partnering with an expert manufacturer is non-negotiable. Companies like Shengxin Aluminium offer not just high-quality materials but deep experience in custom aluminum profiles and alloy solutions. Their commitment to rigorous quality control and advanced testing means you receive aluminum that performs exactly as your design requires—no surprises, no compromises.

In a world where the difference between alum vs aluminium or subtle variations in melting range can make or break a project, trust and technical expertise are your best allies. Always insist on certified, well-documented material from a reputable supplier. That’s how you turn knowledge of the melting temp of aluminum into real-world success—every time.

Pure aluminum melts at 660.32°C (1220.58°F). This value is widely recognized as the benchmark for unalloyed aluminum and is a crucial reference point for manufacturing and engineering applications.

Aluminum alloys are mixtures of aluminum with other elements, which disrupt the pure metal's crystal structure. This causes them to melt over a temperature range—defined by solidus (where melting starts) and liquidus (where fully liquid) temperatures—rather than at a single point. This melting range is important for processes like casting and welding, as it affects how the material behaves under heat.

Impurities such as iron, silicon, copper, magnesium, and zinc can lower the melting point and broaden the melting range of aluminum. This is especially common in recycled aluminum, where mixed scrap can introduce variable impurity levels, impacting both melting behavior and final product quality.

Aluminum has a relatively low melting point compared to metals like steel, copper, and titanium. For example, carbon steel melts between 1371–1593°C, while pure aluminum melts at 660.32°C. This lower melting temp makes aluminum ideal for processes that require less energy, such as extrusion and casting.

Sourcing aluminum from a certified manufacturer ensures consistent alloy composition, reliable melting range, and documented quality. This is essential for achieving the desired performance in fabrication, especially for projects with strict safety or engineering requirements. Reputable suppliers like Shengxin Aluminum provide material certification, technical support, and expertise in alloy selection for optimal results.

serviço on-line

serviço on-line 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360