When you think about combining aluminum and steel, you might wonder: can you weld aluminum to steel? It sounds straightforward, but the answer is more complex than it first appears. If you’ve ever tried directly welding these two metals, you’ll notice the results are often disappointing—cracks, weak joints, or outright failures. So, what’s really happening?

The short answer is that direct fusion welding—using standard processes like TIG or MIG to join aluminum and steel together—is generally not feasible. The reason? When aluminum and steel are fused, they form brittle intermetallic compounds at the weld interface. Imagine trying to glue two pieces of wood together but ending up with a layer of glass in between—no matter how strong the wood or the glue, the joint is only as strong as that brittle glass. In the case of aluminum and steel, this brittle layer can easily crack under stress, making the joint unreliable for most structural or load-bearing applications.

But that doesn’t mean welding aluminum to steel is impossible. Over the years, experts have developed effective workarounds and alternative joining methods. Throughout this guide, you’ll discover:

We’ll explore the science behind the challenges, walk you through each joining method, and help you choose the best solution for your project. Whether you’re tackling a structural fabrication or a simple repair, understanding the limitations and options for welding aluminum to steel will save you time, money, and frustration. Ready to learn more? Let’s dive into why these metals are so tough to join—and how you can do it right.

When you set out to join aluminum and steel, you’re not just connecting two pieces of metal—you’re facing a set of scientific hurdles that make dissimilar metals welding uniquely challenging. Why is it so tough to get a strong, reliable bond between these two materials? Let’s break down the key differences and see why standard welding methods often fall short.

Imagine trying to fit together puzzle pieces from two completely different sets. That’s what it’s like when you attempt to weld aluminum to steel. The core reason lies in their vastly different physical and chemical properties, which create a host of obstacles:

So, what do these differences mean in practice? Here’s how they impact your welding process:

In summary, the aluminum vs steel welding challenges come down to fundamental scientific differences. These aren’t just minor inconveniences—they’re the reason why direct fusion welding between aluminum and steel is rarely successful without special methods or materials. Understanding these challenges is the first step in choosing the right joining technique for your project.

Next, we’ll dive deeper into the metallurgical reasons behind these issues, focusing on the formation of brittle compounds at the weld interface—and what that means for your finished joint.

When you ask, "Why can't you weld aluminum to steel directly?" the answer goes beyond just different melting points. The real obstacle lies in what happens at the microscopic level—specifically, the formation of intermetallic compounds at the weld interface. Let's break this down in simple terms so you can see why these compounds are such a dealbreaker for strong, reliable joints.

Imagine you're trying to glue two pieces of wood together, but before the glue dries, a layer of sharp glass shards forms between them. Even if the glue itself is strong, the joint will always break along the brittle glass. This is exactly what happens when you try to weld aluminum and steel—the "glass shards" are actually brittle intermetallic compounds with names like FeAl3 and Fe2Al5.

Even at temperatures well below aluminum's melting point, iron and aluminum atoms start to diffuse into each other, triggering the growth of these compounds. The process is driven by time and temperature—the longer and hotter the weld, the more intermetallics form. According to recent research, the intermetallic layer's thickness grows in a parabolic pattern as heat exposure increases, directly reducing joint toughness and increasing the risk of cracks or fractures (ACS Publications).

The presence of a thick intermetallic layer essentially acts as a weak link in your weld. Here’s how it impacts your results:

Researchers have shown that adding certain alloying elements or interlayers (like copper or vanadium) can help reduce the formation of Fe-Al intermetallics, but direct fusion welding without such measures almost always leads to compromised joints (ScienceDirect).

To sum up, the main reason why you can't weld aluminum to steel using standard methods is the unavoidable formation of brittle intermetallic compounds at the interface. Any successful joining technique—whether it's using bimetallic transition inserts, specialized brazing, or solid-state welding—must find a way to minimize or eliminate these compounds to achieve a strong, durable bond.

Next, we’ll explore how bimetallic transition inserts are engineered to overcome this metallurgical barrier, enabling true welds between aluminum and steel in demanding applications.

Ever wondered how large ships, high-speed trains, or industrial plants manage to securely join aluminum to steel—despite all the metallurgical barriers? The answer often lies in a specialized solution: bimetallic transition inserts. If you’re aiming for a strong, reliable, and truly welded joint between these dissimilar metals, this is the professional’s choice. Let’s break down what these inserts are, how they’re made, and why they’re the gold standard for demanding applications.

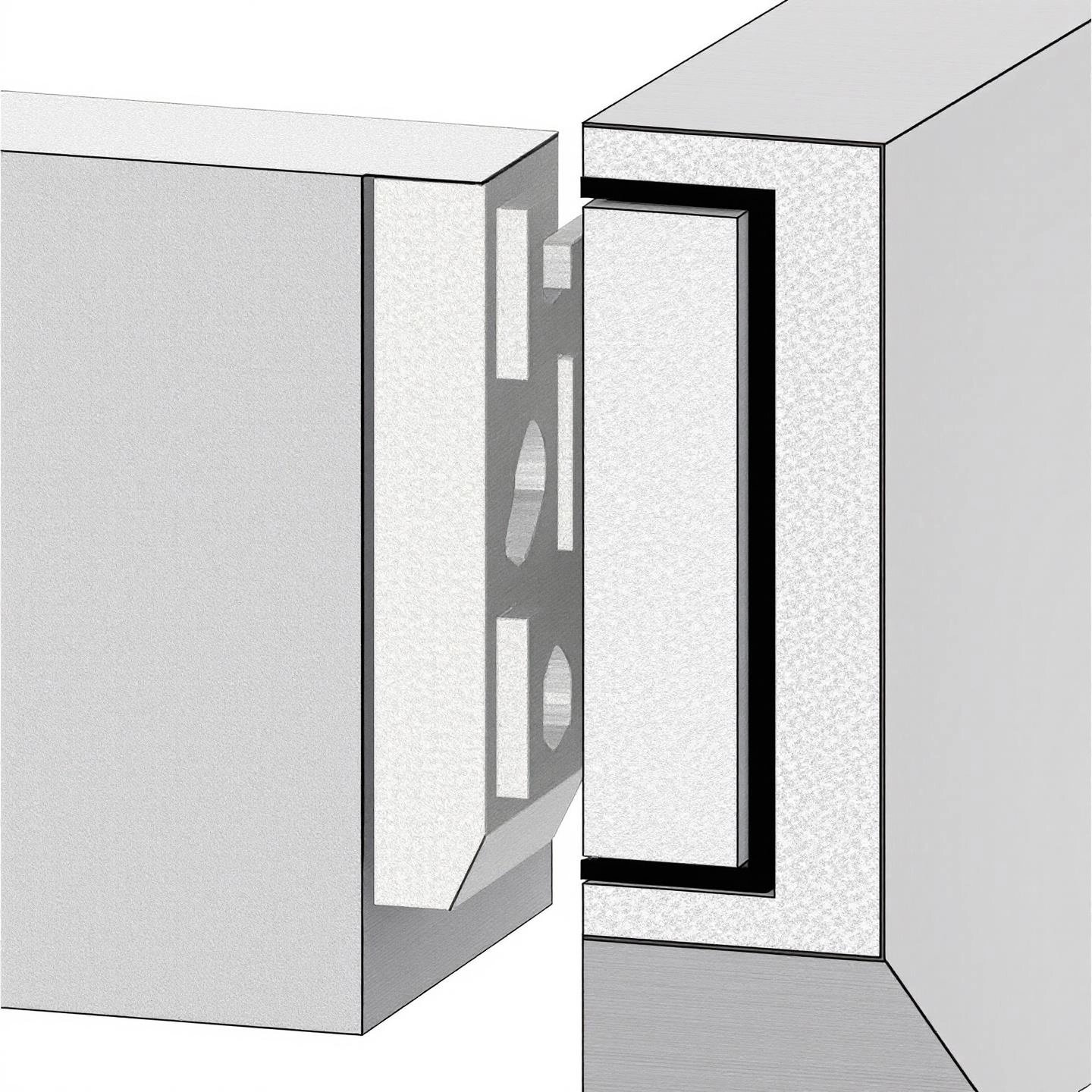

Picture a sandwich where one slice of bread is aluminum and the other is steel, but the two are permanently bonded together at the factory. That’s essentially what a bimetallic transition insert is: a pre-manufactured piece, with one side made of aluminum and the other of steel, seamlessly joined along a common interface. These inserts act as a bridge, allowing you to weld aluminum to aluminum on one side and steel to steel on the other—completely bypassing the formation of brittle intermetallic compounds that plague direct welding.

The most widely used method for creating these inserts is explosion welding. Sounds dramatic? That’s because it is—this process harnesses the immense force of controlled explosives to bond the two metals at a molecular level. Here’s how it works:

Explosion welding is especially valued for its ability to produce large-area, high-strength joints between metals that would otherwise be impossible to fuse directly.

Once the bimetallic transition insert is prepared, the welding process becomes straightforward:

By separating the aluminum and steel welds, you avoid the problematic direct fusion zone entirely. The result? A joint that’s strong, ductile, and suitable for heavy-duty or safety-sensitive applications.

For demanding projects—where the quality and reliability of your aluminum profiles matter just as much as the joint itself—it’s crucial to work with an experienced manufacturer. Companies like Shengxin Aluminum provide high-grade, precision-engineered aluminum profiles that are ideal for integration with bimetallic transition inserts. Their expertise ensures that your structures meet the highest standards for performance and safety.

With bimetallic transition inserts, you’re not just overcoming the metallurgical barrier—you’re building a bridge between aluminum and steel that’s designed to last. Next, we’ll look at the role of TIG welding in this process and why it’s the go-to method for joining the respective sides of the insert to their matching metals.

When you hear about TIG welding, you might wonder: can you TIG weld aluminum to steel directly? The answer is a bit nuanced. TIG welding (also known as Gas Tungsten Arc Welding, or GTAW) is renowned for its precision and ability to produce clean, high-quality welds. But when it comes to joining aluminum and steel, TIG welding alone is not the magic solution—unless you use it as part of a larger, specialized process.

Imagine you’re working with a bimetallic transition insert (as described in the previous section). Here’s where TIG welding truly shines: it’s used to weld the aluminum side of the insert to the aluminum component, and the steel side to the steel component. The key is that TIG welding is applied only to like metals—aluminum to aluminum, steel to steel—not directly between the two dissimilar metals. This approach avoids the brittle intermetallic compounds that form when aluminum and steel are fused together without an intermediary.

This process ensures each weld is strong, ductile, and free from the metallurgical issues that plague direct aluminum-to-steel joints.

So, why is TIG welding the preferred technique for these critical joints? Here’s what sets it apart:

For projects requiring the highest standards—such as aerospace, shipbuilding, or industrial fabrication—TIG welding offers the control and reliability needed to ensure lasting joints between aluminum and steel components (when used with a transition insert or intermediary layer).

To sum up, while you cannot TIG weld aluminum to steel directly, TIG welding plays a vital role in joining these metals when used with bimetallic transition inserts or similar intermediary solutions. It’s the go-to process for creating robust, defect-free welds on each side of the joint, ensuring your finished product is both strong and reliable.

Next, we’ll explore how these principles apply when one of your base metals is stainless steel—and what unique challenges you’ll face in that scenario.

When it comes to aluminum to stainless steel welding, the challenges become even more complex. You might be wondering: can you weld aluminum to stainless steel using the same methods as with regular steel? The short answer is that the core difficulties—like brittle intermetallic compound formation—still apply, but there’s an added layer of complexity due to stainless steel’s unique surface chemistry.

Let’s break it down. Stainless steel earns its corrosion resistance from a thin, stable layer of chromium oxide that forms instantly on its surface. This oxide layer acts like a shield, protecting the metal underneath from rust and corrosion. But when it comes to welding, this shield is a double-edged sword:

So, if you attempt to weld aluminum directly to stainless steel, you’re not only fighting the formation of brittle iron-aluminum intermetallic compounds—you’re also contending with a stubborn oxide barrier that resists fusion.

Given these hurdles, what are the best ways to join aluminum to stainless steel? Here’s what the experts recommend:

It’s worth noting that even with these methods, careful attention to temperature control and joint preparation is crucial. For bimetallic inserts, it’s best practice to weld the aluminum side first, using standard aluminum welding techniques, and then weld the stainless steel side, taking care not to overheat the interface. For brazing, cleaning the chromium oxide layer and using the correct flux or filler is essential for a strong bond.

In summary, while can you weld aluminum to stainless steel is a common question, the answer hinges on using specialized joining techniques. Direct fusion welding is rarely successful due to both the persistent formation of brittle intermetallics and the complications of chromium oxide. Bimetallic transition inserts and carefully controlled brazing remain the most reliable, professional solutions for strong, durable joints between these two metals.

Now that you understand the unique challenges of stainless steel, let’s explore how brazing can serve as a versatile, non-welding alternative for joining aluminum and steel in a range of applications.

When the idea of welding aluminum to steel seems like a dead end, you might wonder if there’s a practical workaround that doesn’t involve complex inserts or advanced machinery. That’s where brazing aluminum to steel steps in—a professional, versatile method used by fabricators and repair specialists alike. But what exactly is brazing, and how does it differ from traditional welding? Let’s break it down.

Imagine you need to join two puzzle pieces that don’t quite fit. Instead of melting them both and fusing them together (as in welding), you use a special molten glue—a filler metal—with a lower melting point than either piece. That’s the essence of the aluminum to steel brazing process:

The process can sound complex, but it’s surprisingly accessible with the right preparation and materials. Here’s a step-by-step overview:

Common techniques include torch brazing for small or intricate parts, furnace brazing for larger or batch processes, and induction brazing for fast, high-volume production.

So, when is brazing the best choice, and where does it fall short? Here’s what you need to know:

| Strengths | Limitations |

|---|---|

|

|

Brazed joints are often strong enough for many practical uses—such as automotive repairs, heat exchangers, and electrical assemblies—but may not match the strength or fatigue resistance of a welded joint with a bimetallic insert.

If you need to join aluminum to steel for non-structural, repair, or moderate-duty applications, brazing offers a reliable, cost-effective solution. It’s especially useful when welding isn’t practical or when minimizing thermal distortion is a priority. However, for critical structural projects, consider bimetallic transition inserts or other advanced joining methods for maximum performance.

Curious about alternatives for non-structural or temporary bonds? Next, we’ll look at how high-strength epoxies and adhesives fit into the aluminum-to-steel joining toolbox.

Ever found yourself needing to join aluminum and steel but lacking the tools—or the need—for heavy-duty welding? That’s where high-strength epoxies, such as JB Weld, come into play. But how do these aluminum to steel adhesives really stack up, and when are they the right choice?

Unlike welding, which fuses metals together at high temperatures, epoxy adhesives form a strong bond by chemically joining the surfaces at room temperature. JB Weld, for example, is a two-part epoxy system: you mix the resin and hardener in equal parts, apply the mixture to both surfaces, and clamp them together. After curing (usually 15–24 hours), the bond becomes solid and can be sanded, drilled, or even tapped.

| Pros | Cons |

|---|---|

|

|

Welding—whether by fusion or using bimetallic transition inserts—creates a metallurgical bond that is far stronger and more reliable for critical or load-bearing projects. Adhesives, on the other hand, are best for non-critical assemblies, repairs, or when joining thin, delicate, or hard-to-access parts. They’re also ideal when you want to avoid heat distortion, preserve surface finishes, or need a quick, accessible solution.

Imagine fixing a cracked aluminum lawn chair, a kitchen utensil, or a non-structural bracket—these are perfect scenarios for a product like JB Weld aluminum to steel adhesive. But if you’re repairing a car frame, engine part, or anything critical to safety, welding or mechanical fastening is the only safe choice.

Choose epoxy adhesives like JB Weld when your project:

For anything more demanding, especially where strength and long-term reliability matter, consider metallurgical joining methods instead. Next, we’ll compare all these joining methods side by side—so you can confidently pick the best approach for your unique application.

When it comes to how to attach aluminum to steel, the right method depends on your project’s requirements—strength, cost, skill level, and end-use all play a role. With so many joining options available, it’s easy to feel overwhelmed. Do you need a joint that’s as strong as the base metals, or is a simple, non-structural bond enough? Let’s break down your options and help you make an informed decision.

To make your choice easier, here’s a direct comparison of the most common professional methods for joining aluminum to steel. Use this table as a quick reference when evaluating your next fabrication, repair, or design project:

| Joining Method | Strength | Required Skill/Equipment | Typical Applications | Notes |

|---|---|---|---|---|

| Bimetallic Transition Insert Welding | Highest—comparable to aluminum or steel welds | High; needs specialized inserts (often explosion welded), TIG/MIG welding skills | Structural fabrication, shipbuilding, rail transit, heavy industry, demanding engineering projects | Most reliable for critical joints; costlier and requires sourcing custom or standard inserts. Consult experienced suppliers for best results. |

| Brazing | Moderate—suitable for many repairs and assemblies, but lower than welded joints | Medium; requires good surface prep, proper flux, and torch/furnace skills | Automotive repairs, HVAC, electronics, light fabrication, non-load-bearing assemblies | Accessible with basic equipment; joint strength depends on filler and prep. Not ideal for high-stress or thick sections. |

| Epoxy/Adhesive Bonding | Low to moderate—sufficient for non-structural or temporary bonds | Low; easy, no special tools or training needed | Household repairs, fixtures, brackets, thin or delicate parts | Quick and simple; not for critical or load-bearing uses. Surface prep is key for lasting results. |

Start by asking yourself a few key questions:

Don’t overlook mechanical fasteners (bolts, rivets, screws) as a robust, low-tech solution for many assemblies. While there are products marketed as "aluminum to steel welding rods," these typically refer to specialized brazing rods or filler materials—not true arc welding rods for direct fusion. Always check the manufacturer’s recommendations and limitations before use.

If your application is safety-critical, involves custom profiles, or requires the highest level of quality and reliability, it’s wise to partner with experienced manufacturers. Companies like Shengxin Aluminum offer not only high-performance, precision-engineered aluminum profiles, but also expert guidance on integrating these profiles with advanced joining solutions like bimetallic transition inserts. Their expertise can help you avoid costly mistakes and ensure your project meets industry standards for strength, durability, and safety.

Ultimately, the best method for attaching aluminum to steel is the one that fits your project’s technical needs, budget, and available resources. By weighing the pros and cons of each approach—and consulting with professionals when needed—you’ll achieve a reliable, lasting joint every time. In the final section, we’ll recap the key takeaways and empower you to make the smartest joining choices for your next project.

After exploring the ins and outs of joining aluminum and steel, you might still be asking: can you weld aluminum to steel in a way that’s strong, safe, and reliable? The answer, as you’ve seen, is nuanced. While direct fusion welding is generally not feasible due to the formation of brittle intermetallic compounds, there are several proven alternatives that let you achieve a durable and functional bond.

Choosing the right technique comes down to understanding your project’s specific requirements—strength, durability, budget, and available skills. Ask yourself: Does your application demand the highest possible joint integrity? Or is a simple, non-permanent bond enough? By answering these questions, you’ll avoid costly mistakes and ensure your finished product meets both performance and safety standards.

If your project involves demanding engineering, custom aluminum profiles, or requires expert advice on the best joining approach, don’t hesitate to consult with specialists or experienced manufacturers like Shengxin Aluminum. Their deep technical expertise and high-quality aluminum solutions can help turn even the most complex joining challenge into a success.

Ultimately, with the right knowledge and resources, you can confidently tackle any aluminum-to-steel joining task—choosing the method that delivers the results your project deserves. Remember, informed decisions lead to stronger, safer, and longer-lasting joints every time.

Direct welding of aluminum to steel creates a brittle layer of intermetallic compounds at the joint, resulting in weak, crack-prone connections that are unsuitable for structural use. Specialized techniques or intermediary materials are needed to achieve a reliable bond.

The most dependable welding method uses bimetallic transition inserts, which are factory-bonded pieces of aluminum and steel. Each side is then welded to its matching metal using standard techniques like TIG or MIG welding, ensuring strength and durability without direct fusion.

Welding aluminum to stainless steel faces the same brittle intermetallic issues as with carbon steel, plus the added challenge of a chromium oxide layer. The most reliable solutions are bimetallic transition inserts or carefully controlled brazing methods.

High-strength epoxies such as JB Weld can bond aluminum to steel for non-structural or light-duty repairs. While easy to use and effective for small fixes, they lack the strength of welded or brazed joints and should not be used for critical or load-bearing applications.

Consider your project’s strength requirements, available skills, and equipment. For structural or safety-critical applications, bimetallic transition inserts are best. For moderate strength needs, brazing is practical, while adhesives are ideal for simple, non-load-bearing repairs. Consulting with a professional aluminum manufacturer like Shengxin Aluminum can help you select the optimal approach.

serviço on-line

serviço on-line 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360